Engineering Blog

ENSER wears many hats. We are an industrial engineering and design firm, a fabrication partner and a mechanical engineering staffing agency. This allows us to provide you relevant and intriguing information about many industries! Keep abreast on new developments across multiple industries.

July 8, 2025

As digital twins and green energy transform industry, discover how to recruit high-potential engineers who are ready to lead in sustainability and smart technology.

June 9, 2025

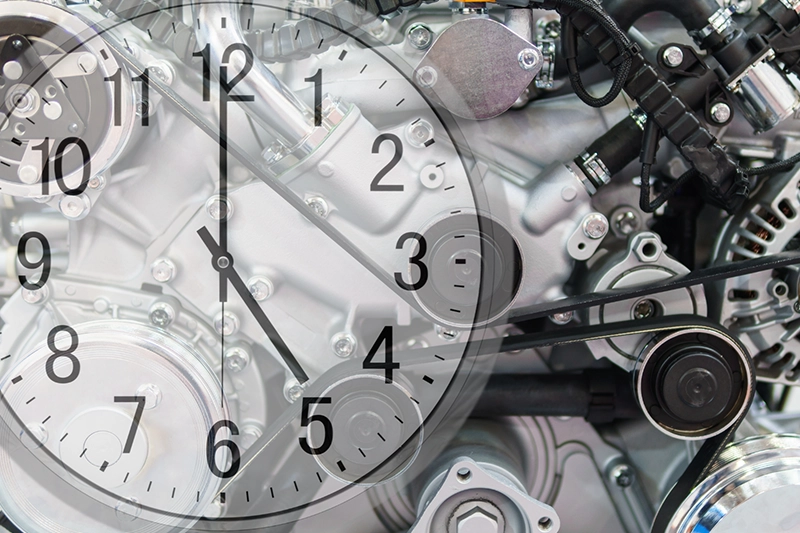

Bottlenecks killing your timeline? Learn how ENSER’s turnkey manufacturing process helps prevent costly delays from the start.

June 5, 2025

Turnkey manufacturing isn’t just a buzzword. Here’s what true CAD-to-crate support really looks like and how ENSER delivers it.

June 4, 2025

Discover the hidden ROI of turnkey manufacturing - from speed and quality to simplified project management.

May 5, 2025

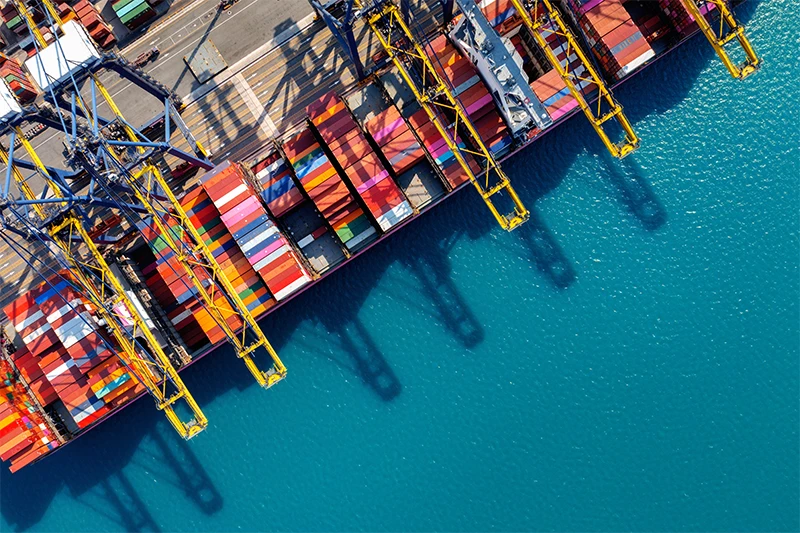

Discover how reshoring manufacturing to the U.S. can combat tariff challenges—and how ENSER’s engineering services support this strategic shift.

April 9, 2025

Discover how AI is revolutionizing engineering recruitment—from faster screening to smarter candidate matching. The future of hiring is here.

March 17, 2025

Discover how to overcome the complexities of contract manufacturing for custom projects. Learn key strategies to manage risk, ensure quality, and optimize production efficiency.

March 5, 2025

Discover insights from ENSER’s President on tackling the energy dilemma. Learn how innovative engineering solutions can optimize energy production and meet rising power demands. Read more here

March 4, 2025

Optimize aerospace operations with ENSER’s turnkey manufacturing solutions, specialized tooling, and IP protection. Learn more today!

February 18, 2025

ENSER delivers engineering, tooling, and staffing solutions to optimize wind turbine manufacturing and renewable energy innovation.

January 27, 2025

Explore the benefits of turnkey manufacturing, from streamlined processes to cost savings, with ENSER’s expert solutions for engineering success.

October 31, 2024

ENSER Corporation Honors 2024 Arnone Scholarship Recipient and Fosters Future Engineering Excellence

Philadelphia, PA, October 31 2024 – ENSER Corporation, a leading name in engineering solutions, proudly commemorates the second anniversary of the Arnone Foundation Scholarship by honoring […]

October 28, 2024

Learn how custom turnkey manufacturing drives innovation in the automotive industry by streamlining production, integrating advanced technologies, and promoting sustainability

October 24, 2024

After almost three decades of dedication, leadership, and hard work, ENSER announces the well-earned retirement of Chip Wilson, our Regional Manager of the North Carolina office

October 14, 2024

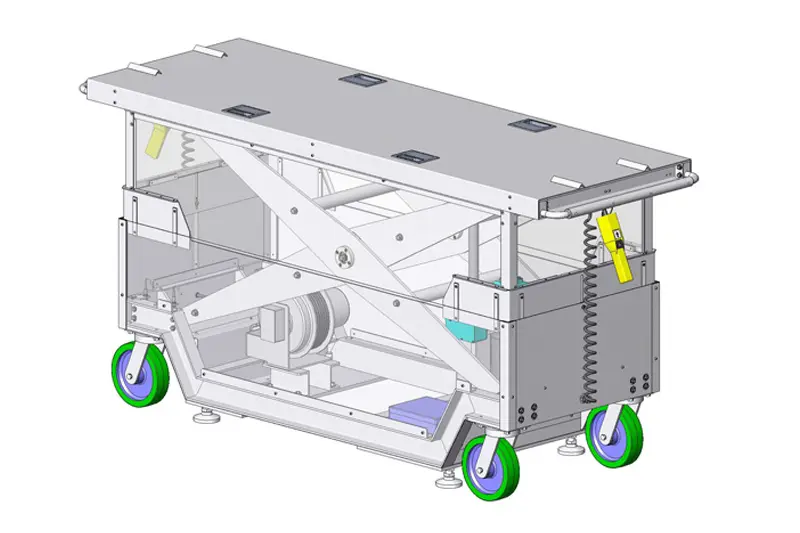

Explore how modular industrial carts solve manufacturing challenges by improving efficiency,safety,and space optimization on the production floor

September 9, 2024

Learn effective strategies for attracting and retaining top engineering talent in today's competitive market. Discover how competitive benefits, a positive culture, and ongoing development can transform your staffing approach.

August 26, 2024

Explore how custom industrial carts enhance both safety and efficiency in the workplace. Learn about the dual benefits of tailored cart solutions for modern industries.

August 12, 2024

Discover how ENSER's innovative approach to below the hook lifting devices has transformed the assembly process for large industrial machinery.

July 29, 2024

Discover how precision fixtures enhance tooling accuracy and ensure top product quality in manufacturing. Explore the critical role of meticulous fixture design

July 15, 2024

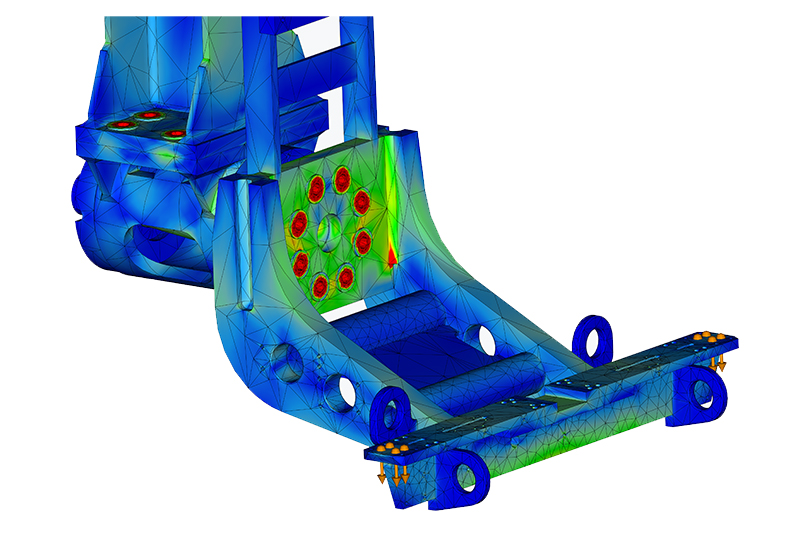

Explore how Finite Element Analysis (FEA) revolutionizes product development in tooling, fixtures, and below the hook devices, saving costs and speeding time to market.