Emerging Technologies in Materials Testing Equipment for Heavy Industries

June 17, 2024

Tooling Accuracy: How Precision Fixtures Shape Product Quality

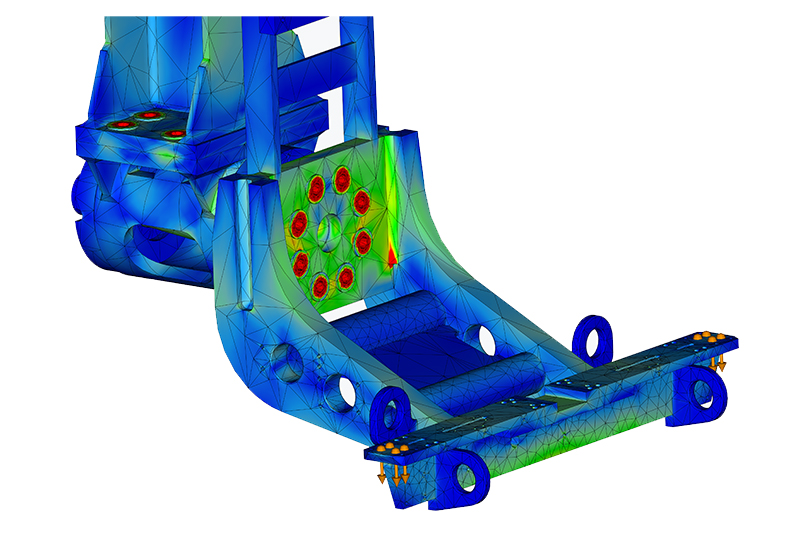

July 29, 2024In the competitive landscape of manufacturing, optimizing the product development process is crucial for success. Finite Element Analysis (FEA) has emerged as a powerful tool, particularly in the development of tooling, fixtures, and below the hook devices. By integrating FEA, manufacturers can not only enhance the design and functionality of these products but also significantly reduce costs and development time. This blog explores how FEA revolutionizes new product development in these specific areas.

The Role of FEA in Product Development

Finite Element Analysis is a computerized method for predicting how a product reacts to real-world forces, vibration, heat, fluid flow, and other physical effects. FEA decomposes a real object into a finite number of discrete elements, which makes complex calculations more manageable and results more precise. This capability is particularly beneficial in the development of tooling, fixtures, and below the hook devices, where structural integrity and operational efficiency are paramount.Cost Reduction with FEA

1. Reduces Prototyping Costs:

Traditional product development often requires multiple prototypes to test different design assumptions, which can be costly and time-consuming. FEA allows engineers to simulate and analyze the physical behavior of a product under various conditions without the need for multiple physical prototypes. This virtual testing environment can lead to a dramatic reduction in the number and complexity of physical prototypes needed, thereby saving material costs and manufacturing time.2. Minimizes Material Usage:

By accurately predicting the stresses and load-bearing requirements of tooling and fixtures, FEA helps in optimizing material usage. Engineers can modify material distribution based on stress concentration areas to ensure durability while eliminating unnecessary material use, which directly translates to cost savings.Time Savings with FEA

1. Accelerates Design Process:

FEA provides detailed insights into performance risks and potential failure points before physical testing or production begins. This enables design teams to make informed decisions quickly, refine designs earlier in the process, and reduce the number of design iterations. Faster validation of designs with FEA leads to shorter product development cycles.2. Enhances Product Optimization:

With the ability to simulate different design scenarios quickly, FEA allows for rapid comparison of multiple design variations. This flexibility helps in finalizing designs faster, ensuring that only the most efficient and effective designs go forward into production.Improving Product Quality and Reliability

1. Predicts Real-World Performance:

Finite Element Analysis simulates actual operating conditions, which helps predict how the product will perform in its working environment. For below the hook devices, which must handle specific loads and movements, FEA simulations ensure that the product can meet required specifications without failure, thereby enhancing reliability and safety.2. Validates Compliance and Safety:

FEA helps in ensuring that products comply with industry standards and safety regulations by providing documented simulations that demonstrate the product’s capability to withstand expected stresses and strains. This is crucial for maintaining compliance with regulatory standards and avoiding costly legal issues related to product failures. Finite Element Analysis improves the way manufacturers develop new products, including tooling, fixtures, and below the hook devices. By leveraging FEA, companies can achieve faster product development times, lower costs, and provide superior product quality. The integration of FEA into product development processes not only provides a competitive edge but also fosters innovation by allowing engineers to explore more complex and robust product designs. At ENSER Corp, FEA is integral to our manufacturing process, especially in the creation of tooling, fixtures and below the hook devices. In fact, FEA is a cornerstone of our engineering strategy, ensuring the products we develop meet the highest standards of performance and safety.Why ENSER Stands Out in Finite Element Analysis

Our commitment to excellence, driven by decades of experience in providing finite element analysis across different industries, positions ENSER Corp as a leader in FEA. Our history of serving diverse industries has equipped us with the insights to create solutions that meet the specific needs of our clients, ensuring their manufacturing processes are as efficient and precise as possible. Finite element analysis is an indispensable tool in achieving streamlined and cost-efficient production, and the expertise ENSER Corp brings to the table in FEA is unmatched.Empowering Innovation: Your Ideas, Your Ownership

We firmly believe in empowering our clients' innovations by ensuring that when we collaborate on a project, the intellectual property (IP) and final products belong entirely to you. This commitment sets us apart in the industry, offering a unique assurance that all designs, tooling solutions, and technological advancements developed in our partnership are yours to own, with no restrictions, retention clauses, or revenue sharing agreements. Ever. We understand the value of your ideas and the importance of maintaining control over your creations. By entrusting us with your projects, you gain not just a service provider, but a partner dedicated to fostering your success while ensuring your innovations remain exclusively yours. This approach not only respects your rights but also encourages a culture of open innovation and trust, paving the way for groundbreaking advancements.Are you ready to integrate advanced FEA strategies into your product development process to save time and reduce costs?

Contact us today to learn how our FEA capabilities can enhance your manufacturing solutions and help bring your products to market faster and more efficiently.