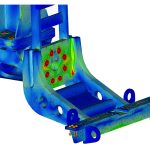

How Finite Element Analysis Saves Costs and Time in New Product Development for Tooling, Fixtures, and Below the Hook Devices

July 15, 2024

Innovative Approach to Below the Hook Solutions for Challenging Industrial Applications

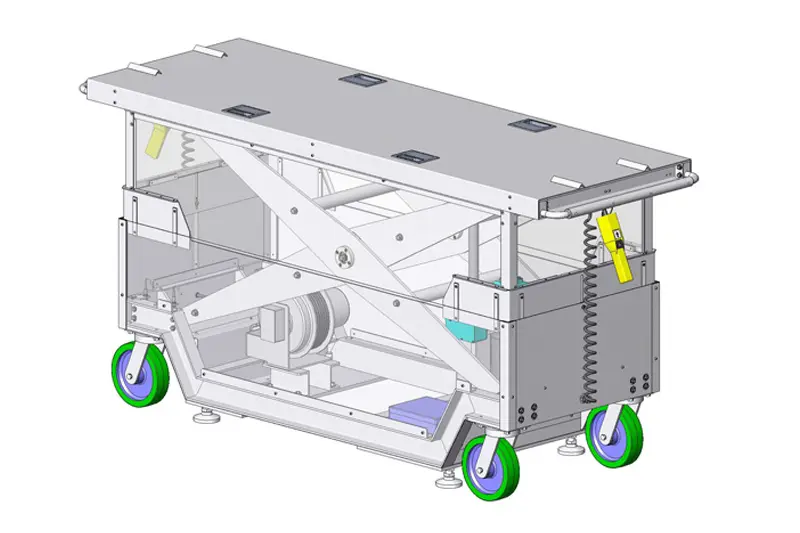

August 12, 2024In mechanical engineering, the quality of the final product is often directly linked to the precision of the tooling and fixtures used during the manufacturing process. Precision fixtures are vital components that ensure accuracy, consistency, and quality in the production of parts and assemblies. This article explores the significant impact that precision fixtures have on product quality and why meticulous attention to tooling accuracy is crucial in mechanical engineering.

The Role of Precision Fixtures in Manufacturing

Precision fixtures are specially designed to hold, support, and locate a workpiece during a manufacturing operation. They are critical in ensuring that components are produced with exactness and uniformity. The primary purpose of a fixture is to maintain the correct positional relationship between a tool and a workpiece during the machining process. This is crucial in industries such as aerospace, automotive, and electronics, where a high degree of precision is essential for the functionality and safety of the final products. Impact on Product Quality1. Dimensional Accuracy

Precision fixtures ensure that each part produced meets the exact specifications outlined in the design drawings. By securing the workpiece in a fixed position, fixtures eliminate the possibility of movement during machining, resulting in highly accurate parts. This accuracy is critical for components that must fit together precisely in complex assemblies, such as in aerospace engineering or microelectronics.2. Consistency Across Production Runs

In mass production, maintaining consistency across thousands of parts can be challenging. Precision fixtures play a pivotal role in replicating the same quality during each production run. They ensure that every piece produced from the first to the last is identical, which is essential for large-scale production where parts must be interchangeable.3. Reduction of Errors and Defects

The use of high-quality fixtures reduces the chances of errors that can occur due to improper alignment or instability during the machining process. This reduction in errors minimizes waste due to defective parts and decreases the cost associated with rework and scrap.4. Enhanced Speed of Production

Precision fixtures are not only about maintaining quality but also about increasing efficiency. With reliable fixtures, machines can operate at higher speeds without compromising the quality of the output. Faster production rates allow companies to meet demand promptly while maintaining high standards of quality.Technological Advancements in Fixture Design

Advancements in technology have significantly influenced the design and functionality of precision fixtures. Computer-aided design (CAD) and computer-aided manufacturing (CAM) systems allow engineers to create more accurate and complex fixture designs that can be customized for specific tasks. Moreover, the integration of automation and robotics in fixture operation has led to improvements in how quickly and accurately fixtures can position a workpiece.Materials and Precision Engineering

The choice of material for constructing fixtures also affects their precision and durability. High-strength alloys, carbon fiber, and advanced polymers are often used based on their mechanical properties and the specific requirements of the manufacturing process. The material must withstand the stresses and strains of operation without deforming, ensuring the fixture's longevity and maintaining accuracy over time.Quality Control and Maintenance

Regular maintenance and quality control are essential to preserve the accuracy of fixtures. Over time, wear and tear can affect a fixture's ability to perform precisely. Routine inspections and maintenance ensure that fixtures remain in optimal condition, delivering consistent performance that meets stringent quality standards. Precision fixtures are fundamental to achieving high-quality manufacturing in mechanical engineering. They directly influence the accuracy, consistency, and reliability of the products produced. As technology continues to advance, the capabilities of these fixtures will only become more critical in meeting the growing demands for precision and efficiency in manufacturing processes. In essence, the quality of a product begins not on the production line, but in the careful design and maintenance of the fixtures that create it.Why ENSER Stands Out in the Tooling and Fixtures Industry

Our commitment to excellence, driven by decades of experience in providing custom tooling and fixture solutions, positions ENSER Corp as a leader in the field. Our history of serving diverse industries has equipped us with the insights to create solutions that meet the specific needs of our clients, ensuring their manufacturing processes are as efficient and precise as possible. Jigs and fixtures are indispensable in achieving streamlined production, and the expertise ENSER Corp brings to the table in designing these tools is unmatched.Empowering Innovation: Your Ideas, Your Ownership

We firmly believe in empowering our clients' innovations by ensuring that when we collaborate on a project, the intellectual property (IP) and final products belong entirely to you. This commitment sets us apart in the industry, offering a unique assurance that all designs, tooling solutions, and technological advancements developed in our partnership are yours to own, with no restrictions, retention clauses, or revenue sharing agreements. Ever. We understand the value of your ideas and the importance of maintaining control over your creations. By entrusting us with your projects, you gain not just a service provider, but a partner dedicated to fostering your success while ensuring your innovations remain exclusively yours. This approach not only respects your rights but also encourages a culture of open innovation and trust, paving the way for groundbreaking advancements.Unlock the Full Potential of Your Manufacturing Process with Precision Tooling!

Contact us today to learn how our FEA capabilities can enhance your manufacturing solutions and help bring your products to market faster and more efficiently.