OUR CUSTOM ENGINEERING DESIGN, MANUFACTURING AND FABRICATION WORK

We take pride in all custom engineering design, manufacturing and fabrication jobs. We consistently deliver intelligent designs and quality engineering products all around the world. Learn more about our products below.

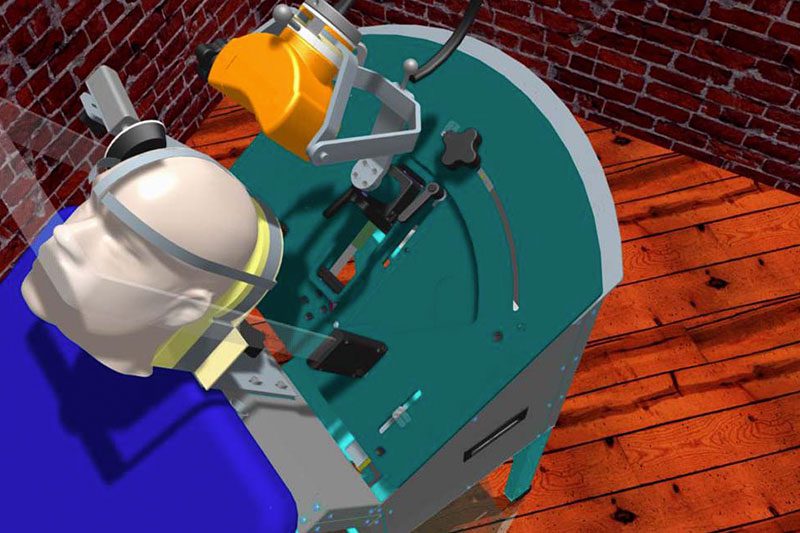

- Custom turbine service tooling improves safety, ergonomics, and service time during transition component replacement in the power generation industry.

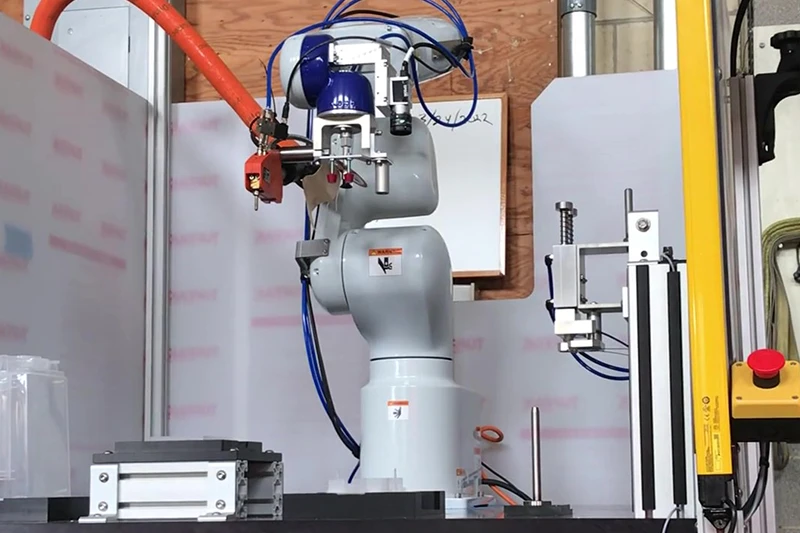

- Automated glue application system designed for medical manufacturing improves precision, repeatability, and efficiency across multiple product variants.

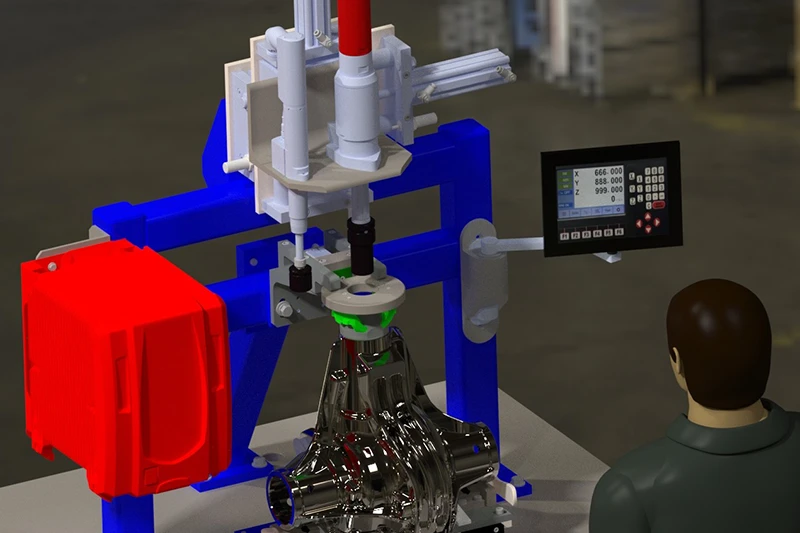

- Custom-engineered automotive torque machine improves cycle time, precision, and safety. Learn how ENSER delivers flexible, operator-friendly solutions.

- There is no excerpt because this is a protected post.

- ENSER has been designing and building fixtures and tools for the Gas Turbine Industry for more than 40 years and plays a critical role in maintenance, upgrades and refurbishing of tools to assure extended lifetime of quality use.

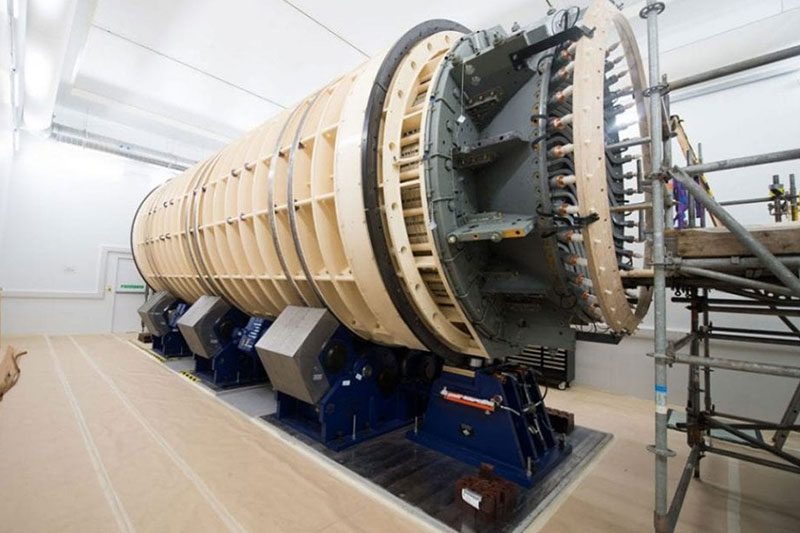

- We engineered a system of power rollers for a massive 300-ton generator for DRAX, a power utility company in the UK. The power rollers were designed to allow the stator core to be rotated as the core is wound, allowing bars to be installed at the optimum position, greatly improving manual handling, safety and quality.

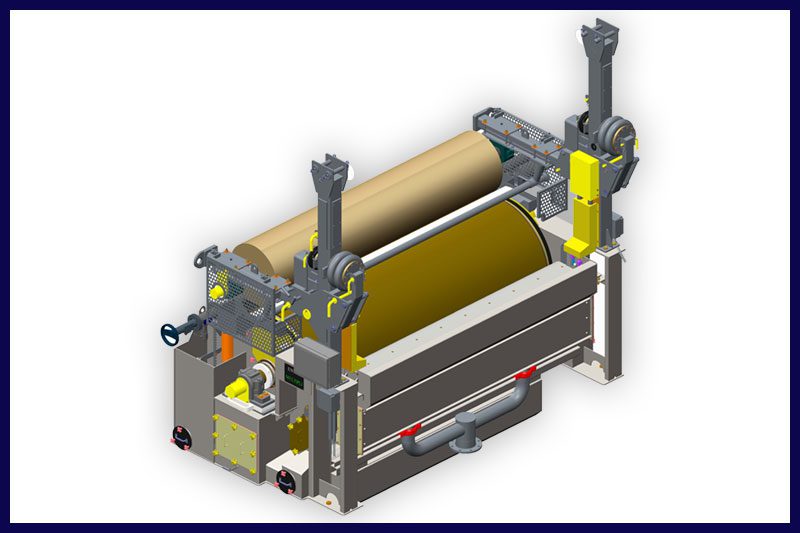

- Background on the Counter Flow Wet Vat The counter flow wet vat project scope was the replacement of existing fiberglass vats with new stainless steel MULTIPLI Counter Flow Wet vats. Each vat included a pneumatic air bellows couch lifting/loading system for use with the existing couch rolls.

- Testing Systems, Rescue Hoists, Industrial Hoists, you name it and we have manufactured it. This is a hoist testing system.

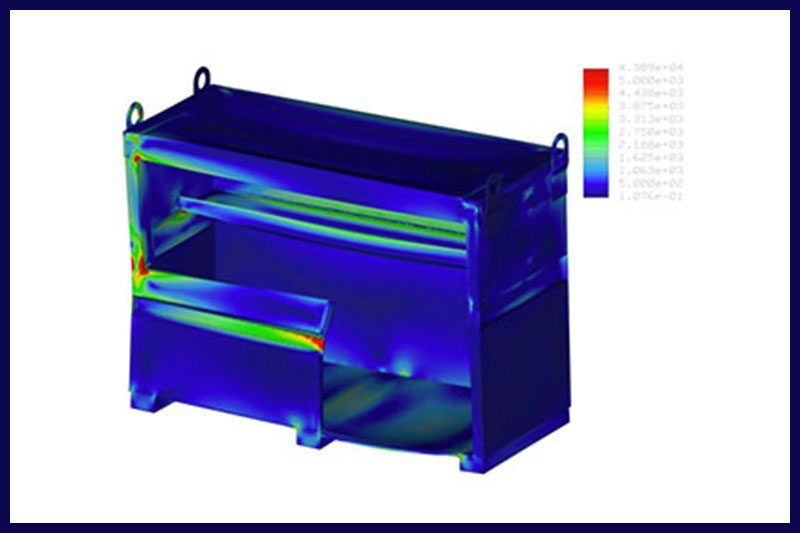

- FEA Analysis (Finite Element Analysis) is an essential part of design and fabrication. Allow ENSER to design and provide FEA for you.

- ENSER was tasked with developing tooling and fixtures that required multiple wires and solder connections be made on a single board without interfering with each other during the process. Flip Jig Fixture had to limit the number of tooling moves per process to reduce operator fatigue.

- ENSER designed and built a fixture to lift and turn down a fully assembled stator housing. The total weight of the turn down fixture and stator was 250 metric tons. The fixture was designed using lightweight high strength material in some areas to cut weight as the crane capacity in the area was at its limit.

- ENSER designed and built this custom transportable bottle capping system. We included controls with a touch screen for adjustments and system monitoring.

- This rotor transport skid was designed and then validated for performance of safe functional operation, overhead lifting, and transportation. Lifting performance included lifting an entire transport skid and rotor system. Lift testing of the unit was completed in its operating conditions at 125% capacity.

- The Neurostar TMS Therapy System technology used in the concept was converted to a design package and built for testing. We manufactured and tested them.

- The lifting beam complies with the ANSI-B 30-20 standard for Below-The-Hook lifting devices and was designed with one center lifting lug for use with 100 ton cranes. The beam length was 360 inches with 13 lifting holes on each side with a total maximum lifting weight of 100 tons.