Counter Flow Wet VAT Replacement Project

Background

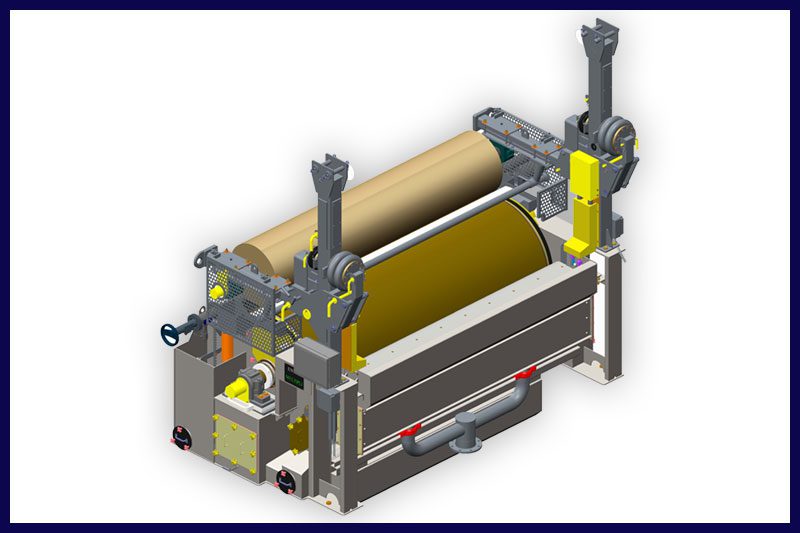

The counter flow wet vat project scope was the replacement of existing 36″ fiberglass vats with new stainless steel 42″ MULTIPLI Counter Flow Wet vats. Each vat included a pneumatic air bellows couch lifting/loading system for use with the existing couch rolls. The machine was also equipped with a MULTIPLI designed automated CD profile control system. Additionally, new framing components were supplied to integrate the new vats into the existing wet end framing structure.

Product

6 42″ MULTIPLI Counter Flow Wet vats

Scope

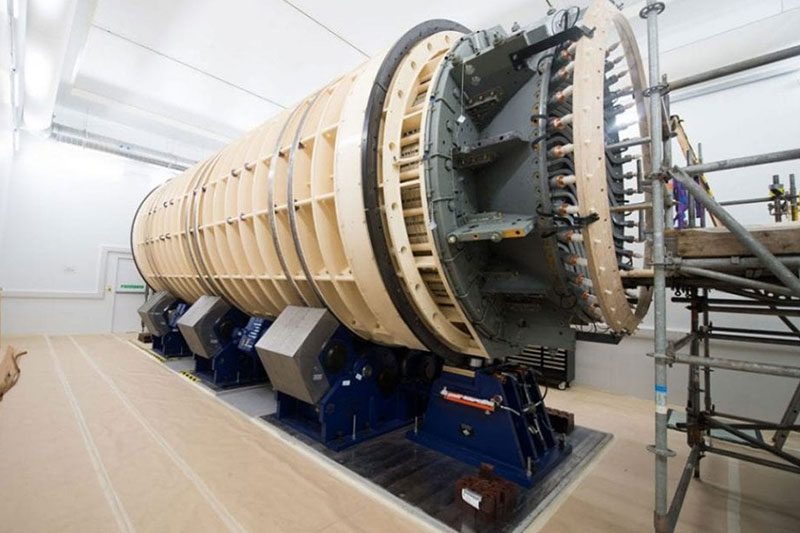

For this project, we partnered with MULTIPLI, the company that pioneered innovations in vat technology and is a leader in supplying many of the vats still in use today. Enser and MULTIPLI partnered to design, manufacture, assemble and deliver 6 MULTIPLI Counter Flow Wet Vats designed for a cylinder of 42″ dia x 108″ face width to replace the much older existing 36″ fiberglass wet vats.

Results

The results were increased mill productivity and higher quality product, which has led to more market share.

- Equipment to operate in a 24 hour, 7 day a week manufacturing environment

- Variation of wet end cross directional profile of 2% – 4% for middle 99 inches of sheet

- Tonnage rate of 112 tons per day based on 25 duro product

- Diameter of cylinders to be 42 inches, face width of 105.5 inches with 104 inches of usable forming area

Engineering Services

Whether you need engineering services for the world's largest power rollers or something smaller, ENSER Corp, has the engineering skills and know-how to complete your project.