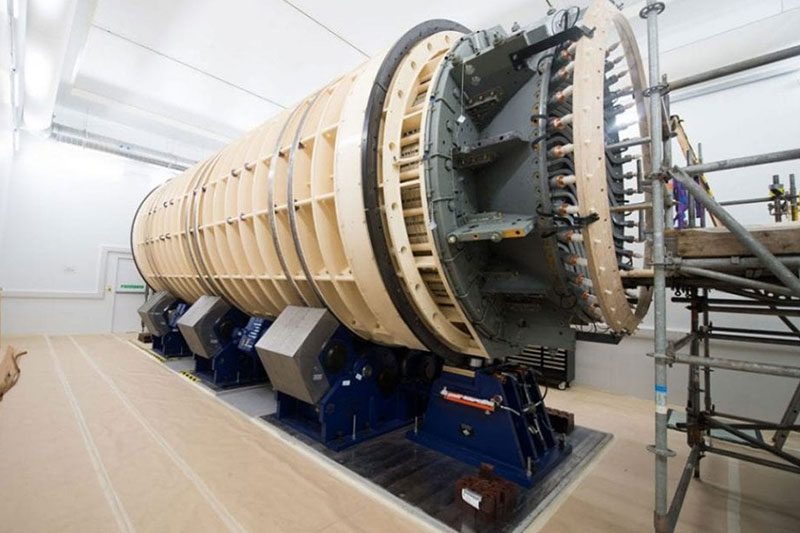

Hoist Testing System

Background

This Automated Hoist Testing System, a type of Below the Hook Lifting (BTH) device, is apparatus used to test and verify the performance, safety, and reliability of various lifting devices, such as the hoists used by search and rescue helicopters, lifting beams, spreader bars, and lifting clamps. These testing devices are crucial in ensuring that the below the hook lifting equipment complies with industry standards and safety regulations, and that they can safely handle specified loads.

Product

Hoist Testing System. The system is capable of operating hydraulic powered hoists using DC powered hoists and 400Hz AC powered hoists, commonly found in search and rescue helicopters.

Challenges

Expanding Product Line Certification: One of the primary pain points our customer faced was the limitation of older equipment, which could certify only a limited portion of their product line—typically 3 or 4 SKUs. Our challenge was to design a new machine capable of accommodating 31 unique SKUs, providing the scalability needed for their growing product range.

- Manual Test Data Recording: The cumbersome process of manually recording test data was a significant bottleneck in their operations, prone to human errors and time-consuming.

- Operator-Dependent Test Results: The variability in test results caused by different testing operators was a major concern, affecting the consistency and reliability of their product quality assessments.

- Inconsistent Equipment Performance: Their existing equipment exhibited inconsistent performance, lacking robustness and repeatability in testing processes.

Solution

ENSER Corp designed, built, assembled, tested and installed a hoist testing system. The system has the capability of operating hydraulic powered hoists, DC powered hoists and 400Hz AC powered hoists. When a unit is connected to the system, it is automatically detected. The system will load the unit’s control software, acceptance procedures and operational safety limits. By doing all of this, the operator does not need to worry about anything other than installing the unit and clicking “Run” to execute a full test procedure. Leveraging our expertise our team implemented a series of techniques and procedures to address the customer’s pain points effectively:

- Enhanced Test Cycle Measurement: We incorporated updated provisions for test cycle measurement capture, ensuring precise and consistent results.

- Automated Data Acquisition: Manual data entry became a thing of the past. We implemented automated data acquisition and logging, generating every-article test reports with unparalleled accuracy.

- Forward-Looking Engineering Capabilities: Our solution featured cutting-edge mechanical and electrical systems, designed with an eye toward future advancements in hoist testing technology.

- Modular Design: To facilitate ease of shipping and installation, we embraced a modular design approach, making it simpler to adapt the system to various operational environments.

- Structural Simulation: Critical components underwent thorough structural simulation to validate the technical design solutions, ensuring safety and reliability.

Benefits to Our Customer

The implementation of a cutting-edge hoist testing solution brought about several transformative benefits for our customer:

- Expanded Product Certification: With the ability to certify 31 unique SKUs, our customer can now meet the demands of a growing product line, capturing more market opportunities.

- Streamlined Operations: Automation of data acquisition and logging eliminated manual errors and reduced testing time, leading to increased efficiency and reduced downtime. This alone reduced labor costs by 33%.

- Consistent and Reliable Results: The elimination of operator-dependent variability ensured that every test produced consistent, reliable results, with accuracy increasing by 23%, contributing to enhanced product quality.

- Robust and Repeatable Testing: Our solution's robustness and repeatability improved the overall reliability of the testing process, reducing the risk of faulty product evaluations.

- Future-Proofed Technology: The forward-looking design of the system ensures that our customer can easily adapt to future advancements in hoist testing, staying competitive in a rapidly evolving industry.

ENSER Corp's innovative solution for hoist testing not only resolved longstanding issues but also positioned our customer for sustained growth and excellence in their field, reaffirming our role as a partner in precision and productivity across various industries. Contact us for a quote on engineering services, manufacturing, and technical staffing just like this hoist testing system. Expect a same day response or call us today at (877) 367-3770.

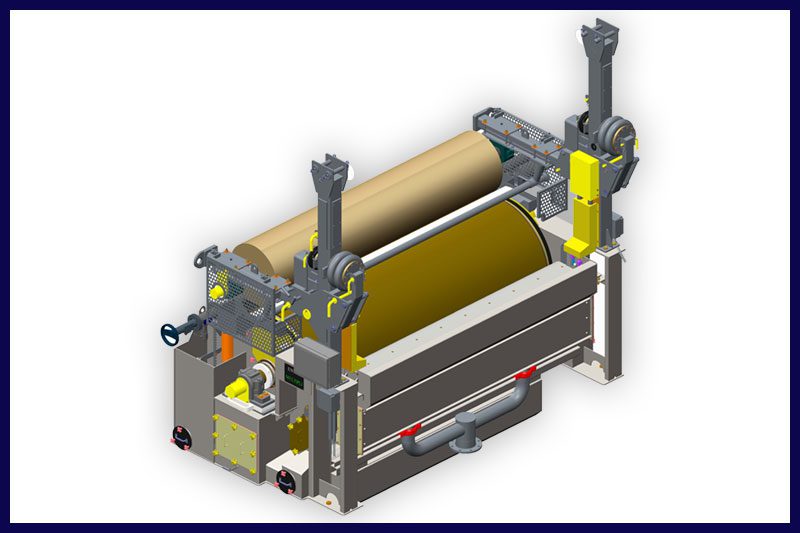

Project Gallery

Engineering Services

Whether you need engineering services for the world's largest power rollers or something smaller, ENSER Corp, has the engineering skills and know-how to complete your project.