Bridging the Skills Gap with Innovative Staffing Solutions in Engineering

June 3, 2024

How Finite Element Analysis Saves Costs and Time in New Product Development for Tooling, Fixtures, and Below the Hook Devices

July 15, 2024In heavy industries such as aerospace, automotive, defense, power generation and others, the integrity and performance of materials are non-negotiable. As technology evolves, so does the equipment used to test and verify the quality and durability of these materials. Today, several emerging technologies are setting new standards in materials testing, offering unprecedented precision, efficiency, and insights. This blog explores these technologies and their impact on tooling and fixtures in heavy industries.

The Critical Role of Materials Testing

Materials testing is pivotal in heavy industries for multiple reasons: ensuring safety, complying with regulatory standards, and enhancing product performance. The stakes are incredibly high, as material failures can lead to catastrophic outcomes, including financial loss, environmental damage, and even loss of life. As such, the tools and technologies used in materials testing must not only be robust but also incorporate the latest advancements to handle the demanding requirements of heavy industries.Emerging Technologies Transforming Materials Testing

Digital Twin Technology

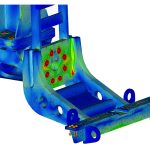

One of the most significant advancements in materials testing is the adoption of digital twin technology. Digital twins create precise virtual models of physical objects or systems, which can be used to simulate real-world conditions and predict how the materials will perform under various stresses without physical testing. This technology not only speeds up the testing process but also reduces the costs associated with physical prototypes.Automated Testing Systems

Automation in materials testing equipment is another leap forward. Automated systems can perform repetitive tasks with minimal human intervention, increasing the throughput and accuracy of testing procedures. For industries that require extensive testing under controlled conditions, automation ensures consistency and eliminates the potential for human error.High-resolution Imaging

Advancements in imaging technology have revolutionized the way materials are inspected. High-resolution cameras and scanning devices now allow for deeper insights into material properties at a microscopic level. Techniques such as 3D X-ray imaging and computed tomography (CT) provide detailed internal views of materials, identifying potential weaknesses and failures before they become problematic.AI and Machine Learning

Artificial intelligence (AI) and machine learning are increasingly being integrated into materials testing equipment. These technologies can analyze data from tests much faster than human operators, identifying patterns and predicting outcomes with high accuracy. AI can also adjust testing parameters in real-time, optimizing the process to yield the best results.Environment Simulation Equipment

Modern materials testing often requires simulating the environmental conditions in which the material will be used. State-of-the-art environmental simulation chambers can mimic a wide range of conditions, from extreme temperatures and pressures to humidity and corrosion environments. These tests are crucial for materials intended for use in harsh or variable conditions.Impact on Tooling and Fixtures

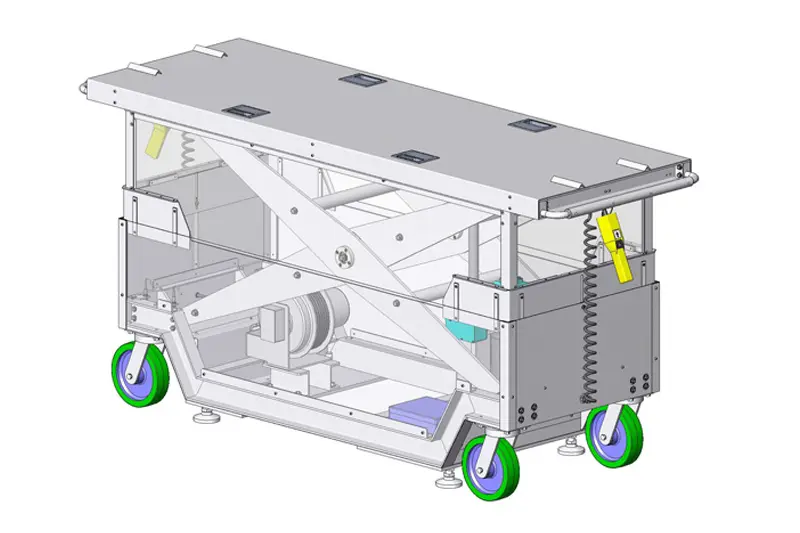

The advancements in materials testing equipment have a direct impact on the design and production of tooling and fixtures in heavy industries. With more accurate testing results, engineers can design tools and fixtures that are not only more durable and effective but also optimized for specific applications, like this Automated Hoist Testing System. This leads to improved efficiency in manufacturing processes and extends the lifespan of the tools and fixtures used.Challenges and Considerations

Despite the advancements, there are challenges in integrating new technologies into existing testing frameworks. The initial cost of upgrading equipment can be significant, and there is often a learning curve associated with adopting new technologies. Moreover, as testing procedures become more complex, the need for specialized training and expertise becomes more pronounced. Emerging technologies in materials testing are reshaping the landscape of heavy industries. By embracing these innovations, companies can enhance the quality and safety of their products, reduce costs, and stay competitive in a fast-evolving market. As these technologies continue to evolve, they promise to bring even more profound changes to the way materials are tested and evaluated in the future.Why ENSER Stands Out in the Custom Tooling Solutions Industry

Our commitment to excellence, driven by decades of experience in providing custom tooling and fixture solutions, positions ENSER Corp as a leader in the field. Our history of serving diverse industries has equipped us with the insights to create solutions that meet the specific needs of our clients, ensuring their manufacturing processes are as efficient and precise as possible. Jigs and fixtures are indispensable in achieving streamlined production, and the expertise ENSER Corp brings to the table in designing these tools is unmatched.Empowering Innovation: Your Ideas, Your Ownership

We firmly believe in empowering our clients' innovations by ensuring that when we collaborate on a project, the intellectual property (IP) and final products belong entirely to you. This commitment sets us apart in the industry, offering a unique assurance that all designs, tooling solutions, and technological advancements developed in our partnership are yours to own, with no restrictions, retention clauses, or revenue sharing agreements. Ever. We understand the value of your ideas and the importance of maintaining control over your creations. By entrusting us with your projects, you gain not just a service provider, but a partner dedicated to fostering your success while ensuring your innovations remain exclusively yours. This approach not only respects your rights but also encourages a culture of open innovation and trust, paving the way for groundbreaking advancements.Stay Ahead of the Curve by Leveraging the Latest Technologies

Contact us today to learn how our advanced tooling and fixtures can benefit your projects in heavy industries.