Part 2 – The Role of Precision Tooling in Mechanical Engineering: Ensuring Accuracy, Repeatability and Efficiency

July 19, 2023

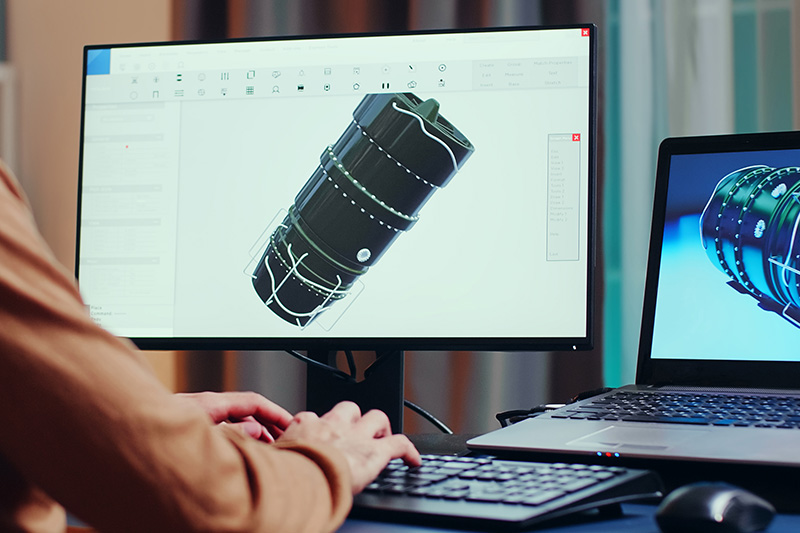

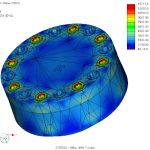

Precision Engineering: Achieving Accurate Results with FEA Simulations

August 14, 2023In the realm of engineering, efficiency and safety are paramount. One crucial aspect of achieving these goals is selecting the appropriate below the hook lifting equipment. Whether you are handling heavy loads, rigging materials, or optimizing material handling processes, the right lifting equipment can significantly impact your operations. At ENSER Corp, we understand the significance of below the hook (BTH) lifting equipment and its role in enhancing productivity while prioritizing safety. In this comprehensive guide, we will delve into the world of below the hook lifting equipment (sometimes referred to as BTH devices or BTH fixtures), exploring the various types available, key considerations, and best practices for selecting the ideal equipment for your specific needs. Let's explore the possibilities together and revolutionize your lifting operations.

Understanding Below the Hook Lifting Equipment

Types of Below the Hook Lifting Equipment

Lifting Beams: Lifting beams, also known as spreader beams, distribute loads evenly and prevent load bending during lifting. They are particularly useful when dealing with wide or irregularly shaped loads, ensuring stability and safety, like the 300-Ton Lifting Beam we designed for a customer in the energy sector.

Spreader Bars: Spreader bars are designed to increase the lifting point and create an evenly distributed lifting load. They are suitable for large or long loads, allowing for efficient and balanced material handling.

Lifting Clamps: Lifting clamps are used to securely grip and lift materials, such as plates, sheets, and pipes, without the need for slings or chains. They offer a safer and more efficient solution for handling various types of loads.

Crane Attachments: Crane attachments, such as hooks, blocks, and shackles, are essential components that connect loads to cranes, providing a strong and reliable lifting connection.

Hoisting Equipment: Hoisting equipment, such as electric chain hoists and wire rope hoists, provide vertical lifting capabilities, making them ideal for tasks that require precise and controlled lifting. Hoisting equipment testing, like the Automated Hoist Testing System used in search and rescue operations, like in the Sikorsky MH-60 Jayhawk operated by the US Coast Guard.

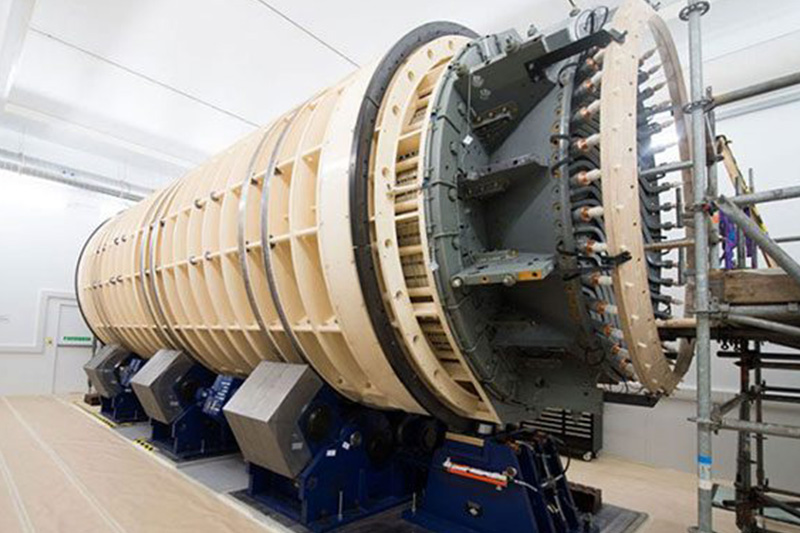

Rotor Transport Skids: Rotor transport skids refers to specialized equipment designed to handle rotors or rotating machinery safely and efficiently during transportation or installation. These skids, like the 35-ton Rotor Transport Skid we built for a power generation company, are engineered with robust construction and lifting points, allowing them to securely support and carry heavy rotors with precision and stability.

Key Considerations for Selecting Below the Hook Lifting Equipment

Load Capacity and Size: Ensure the lifting equipment's capacity matches the weight and size of the loads you will be handling. Overloading can lead to hazardous situations, so accuracy in load calculations is critical.

Material Compatibility: Consider the type and material of the load, as certain lifting equipment may be better suited for specific materials. For instance, lifting clamps are ideal for gripping metal plates, while spreader bars are suitable for diverse loads.

Safety Features and Compliance: Prioritize safety by selecting BTH lifting equipment that complies with industry standards and regulations. Look for additional safety features like automatic locking mechanisms and overload protection.

Environment and Application: Evaluate the working environment and application requirements to ensure the lifting equipment can withstand the conditions it will be exposed to, such as extreme temperatures or corrosive environments and high-duty cycles.

Ease of Use and Maintenance: Choose equipment that is user-friendly and easy to maintain, reducing downtime and enhancing overall efficiency.

The Advantages of BTH Lifting Solutions

Improved Productivity: Efficient lifting solutions can significantly streamline material handling processes, reducing downtime, and improving overall productivity.

Enhanced Safety: By using the appropriate below the hook lifting equipment, potential hazards and risks during lifting operations are minimized, safeguarding both personnel and materials.

Precise Load Control: BTH lifting equipment offers precise load control, allowing for delicate or complex operations that require accurate positioning.

Increased Load Capacity: Lifting equipment can increase the load capacity of cranes, optimizing lifting capabilities for larger and heavier loads.

For more details on the advantages of below the hook lifting devices, please see our previous post Top 5 Advantages of Below the Hook Lifting Devices.