Choosing the Right Below the Hook Lifting Equipment: A Comprehensive Guide

August 7, 2023

Innovative Tooling and Fixtures Solutions in Mechanical Engineering

August 25, 2023In the realm of modern engineering, where precision and accuracy are the cornerstones of innovation, the art of precision engineering shines as a beacon of meticulous craftsmanship and scientific rigor. It's a realm where every curve, every joint, and every material choice are scrutinized to achieve engineering excellence. At the heart of this pursuit lies Finite Element Analysis (FEA)—a remarkable methodology that empowers engineers to dive into the intricate details of structural behavior, ensuring accuracy, optimizing designs, and upholding the paramount concept of structural integrity.

A Glimpse into Finite Element Analysis

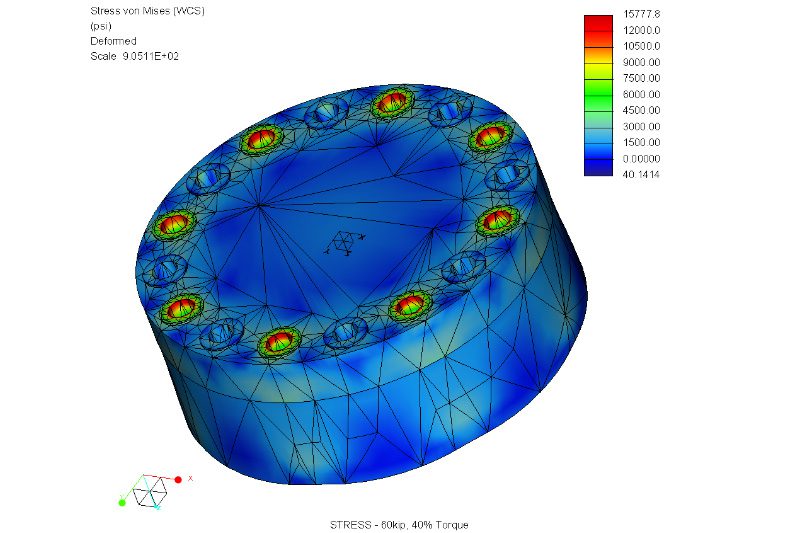

At the heart of precision engineering lies the art of FEA. Finite Element Analysis is a numerical method used to simulate the behavior of complex structures and systems, breaking them down into smaller, more manageable elements. This process involves discretizing a continuous structure into finite elements interconnected at specific points called nodes. By solving the equations governing these interconnected elements, FEA provides valuable insights into how a structure responds to various loads, stresses, and forces.

The Quest for Accuracy in Engineering

In the realm of engineering, precision and accuracy are the guiding principles. FEA serves as a cornerstone for achieving these goals. By virtually modeling intricate components and systems, engineers can analyze real-world scenarios without resorting to costly physical prototypes. This allows for an in-depth understanding of how different design variations affect structural performance.

Structural Integrity: Where FEA Comes into Play

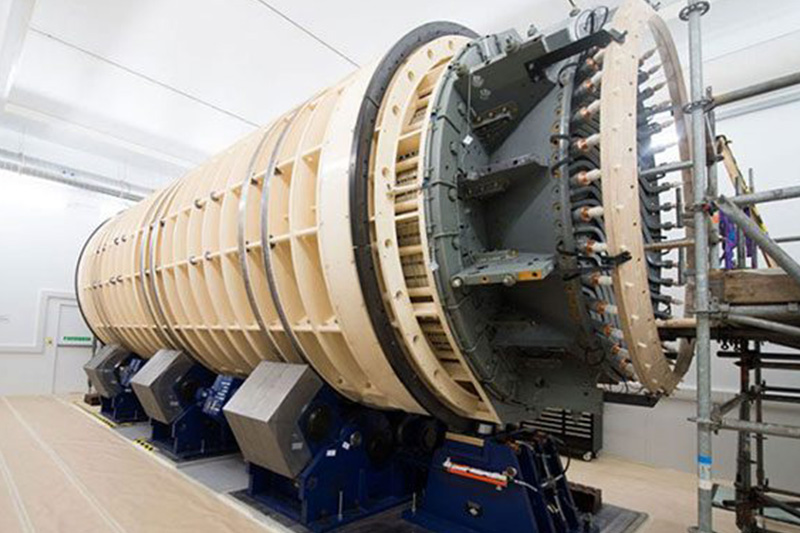

Ensuring the structural integrity of any design is paramount. Whether it's a towering skyscraper, a cutting-edge aerospace component, or a life-saving medical device, FEA plays a pivotal role in scrutinizing every element's behavior under various conditions. By subjecting a virtual prototype to stress and strain analysis, engineers can pinpoint potential weak points, areas of excessive deformation, or material failures. This invaluable information guides design iterations and optimizations, resulting in enhanced structural integrity. Finite Element Analysis (FEA) has a wide range of real-world applications across various industries, contributing to improved design, performance, and safety. Here are some notable examples:

- Aerospace and Aviation: FEA is extensively used to analyze aircraft structures, ensuring they can withstand different loads, pressures, and vibrations. It helps optimize lightweight designs while maintaining structural integrity, enhancing fuel efficiency and safety.

- Automotive Industry: FEA plays a crucial role in designing and testing automotive components, from engine parts to chassis systems. It aids in crash simulations, durability assessments, and optimizing vehicle performance.

- Civil Engineering: In civil engineering, FEA helps analyze and design structures like bridges, dams, and buildings. It ensures their stability, load-bearing capacity, and resistance to environmental factors such as earthquakes and wind.

- Medical Device Development: FEA is employed to simulate and analyze the behavior of medical implants, prosthetics, and surgical instruments. It ensures biocompatibility, durability, and functionality in healthcare applications.

- Consumer Electronics: FEA is used in the design and testing of consumer electronics such as smartphones, laptops, and wearable devices. It helps predict heat dissipation, impact resistance, and overall product reliability.

- Energy Sector: FEA aids in optimizing components of energy systems, such as wind turbine blades, ensuring their ability to withstand various forces and environmental conditions. It's also used in analyzing heat exchangers and nuclear reactor components.

- Oil and Gas Industry: FEA is vital for analyzing the structural integrity of offshore platforms, pipelines, and drilling equipment. It ensures safety, durability, and efficient operation in harsh environments.

- Manufacturing Processes: FEA is applied to study manufacturing processes like metal forming and casting. It helps predict material deformation, stress distribution, and potential defects in the final products.

- Biomechanics and Sports Equipment: FEA assists in designing sports equipment such as helmets, footwear, and protective gear. It ensures optimal performance, impact absorption, and user comfort.

- Material Development: FEA aids in understanding material behavior under various conditions, guiding the development of new materials with enhanced properties.

- Manufacturing Process Optimization: FEA is used to optimize manufacturing processes such as metal forming, casting, and injection molding. It helps predict material flow, stresses, and defects during production.

- Structural Rehabilitation: FEA aids in evaluating the structural integrity of aging infrastructure and proposing rehabilitation strategies to extend their service life.

- Machine Design: Engineers use FEA to optimize the design of machines, ensuring they can handle complex motions, forces, and loads while minimizing vibration and wear.

- Packaging Design: FEA helps optimize packaging designs to protect fragile or sensitive products during transportation and storage.