Unlock Your Engineering Career Potential with ENSER & The Resume Team

March 12, 2024

Optimizing Efficiency: The Art of Tooling Design with Jigs and Fixtures. Learn the Best Practices Gained From our 77 years of Experience

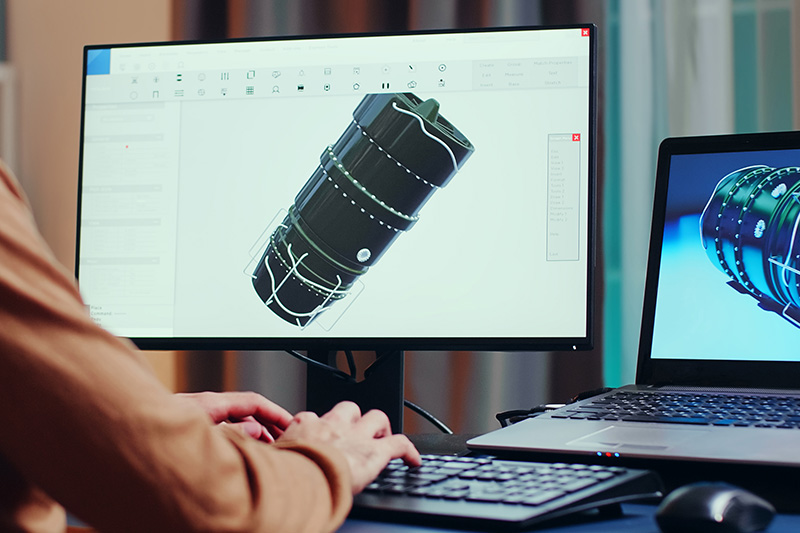

March 25, 2024Finite Element Analysis (FEA) emerges as a cornerstone of modern design and analysis, and its role in modern engineering cannot be overstated. At ENSER, a pioneer in engineering solutions since 1947, we leverage FEA services to transform concepts into reality, ensuring safety, reliability, and performance in structural analysis. Our commitment to excellence, powered by state-of-the-art FEA capabilities, ensures that we turn conceptual challenges into tangible successes for our clients. This article explores the depth and breadth of FEA services, shedding light on how they drive innovation in mechanical engineering analysis.

The Essence of FEA in Engineering

FEA represents a pinnacle of simulation software technology, allowing engineers to conceptualize, test, and optimize designs before the first piece of material is ever cut. Through FEA modeling, complex structural behaviors under various conditions are predicted, including stress, strain, and displacement. This "virtual testing ground" is critical for identifying potential issues and making improvements early in the design process, saving time, resources, and, most importantly, lives.Key Areas of FEA Services

- Structural Analysis: Understanding the response of structures under loads is vital. Our structural analysis expertise ensures your designs withstand both expected and unexpected forces.

- Stress Analysis: Every component's longevity and safety depend on its ability to endure stress. Our stress analysis services pinpoint high-stress areas, guiding improvements to enhance durability and reliability.

- FEA Modeling and Simulations: Our FEA modeling services bring your designs to life, simulating real-world conditions to predict performance accurately. With advanced FEA simulations, we provide insights that drive structural optimization, ensuring your projects meet stringent performance criteria.

Applications of FEA in Various Industries

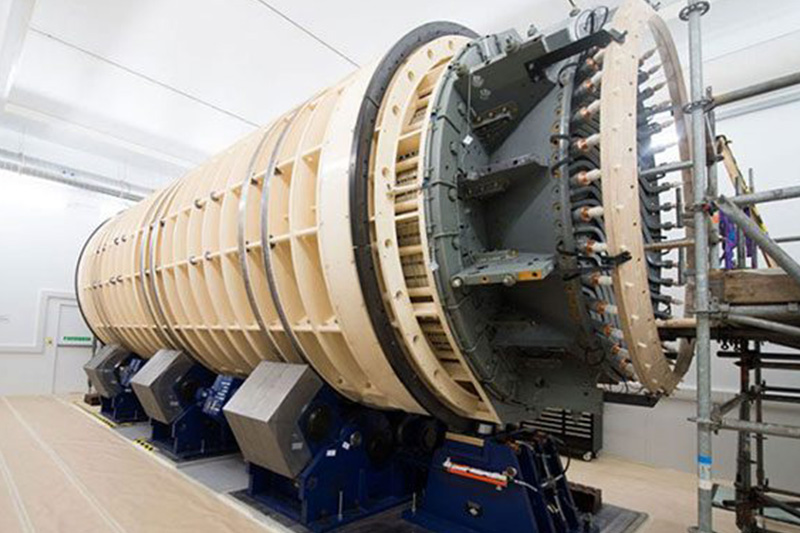

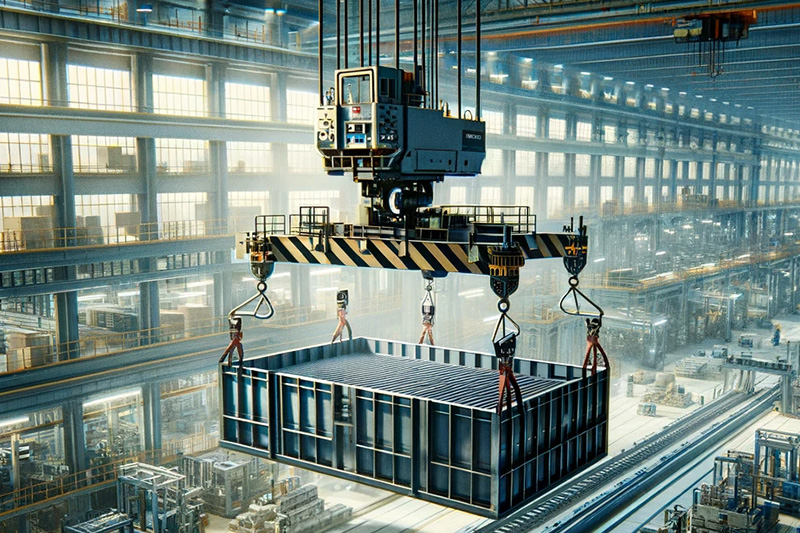

Finite Element Analysis (FEA) services are indispensable across a wide range of industries, demonstrating the versatility and critical importance of this technology in addressing complex engineering challenges. From power generation to aerospace, automotive, and general manufacturing, FEA's impact is profound. Moreover, its application in the design and analysis of "below the hook lifting devices" such as spreader bars and lifting beams underscores its value in ensuring operational safety and efficiency.- Power Generation Industry: FEA aids in optimizing components like wind turbine blades for maximum efficiency and reliability. In nuclear facilities, it ensures the structural integrity of containment vessels, enhancing safety and operational longevity.

- Automotive Industry: The automotive sector relies on FEA for crash simulation analyses, optimizing vehicle design for safety and performance. It also facilitates the development of lightweight, durable components, contributing to vehicle efficiency.

- Aerospace Industry: In aerospace engineering, FEA is crucial for designing aircraft and spacecraft capable of withstanding extreme conditions. It optimizes structural components for strength and weight and simulates thermal stresses for spacecraft re-entry.

- General Manufacturing: FEA's role in general manufacturing spans the optimization of consumer electronics for durability and the design of heavy machinery for reliability, ensuring products meet high standards of quality and efficiency.

- Below the Hook Lifting Devices: FEA's application extends to designing and analyzing below the hook lifting devices, such as spreader bars and lifting beams. These devices are critical for safely lifting and transporting heavy loads in various industrial settings, including construction sites, manufacturing plants, and warehouses. FEA simulations help in predicting how these devices will perform under load, ensuring they can handle the weight and distribution without failing. For spreader bars and lifting beams, FEA is used to analyze structural integrity, load distribution, and potential points of failure. This analysis is crucial for optimizing the design for weight efficiency while ensuring safety and compliance with industry standards. By accurately modeling the stress, strain, and displacement these devices will experience, engineers can make informed decisions on materials, dimensions, and reinforcements needed to meet operational requirements. Learn more about using spreader bars for safe and efficient material handling.

The Finite Element Method: A Closer Look

At the heart of FEA lies the Finite Element Method (FEM), a sophisticated technique that divides a complex problem into smaller, manageable "elements." This method provides a detailed view of how structures behave under various conditions, offering unparalleled insight into areas requiring reinforcement or redesign for optimal performance.Structural Optimization: Beyond Analysis

FEA isn't just about identifying problems; it's also about providing precise solutions. Structural optimization is a critical phase where the data from FEA simulations inform design improvements, enhancing efficiency, reducing costs, and improving performance. Learn more about achieving results with FEA simulations. At ENSER, we don't just analyze; we innovate, using FEA to guide the evolution of your projects from concept to reality.Why Choose ENSER for FEA Services?

Choosing ENSER for your FEA needs means partnering with a team that brings decades of experience, cutting-edge technology, and a commitment to excellence to every project. Our deep understanding of the finite element method, combined with a client-centric approach, ensures tailored solutions that meet your unique requirements. FEA's role in modern engineering cannot be overstated. It serves as a critical tool in the engineer's arsenal, facilitating the seamless transition of ideas from the drawing board to real-world application. At ENSER, leveraging FEA's advantages is integral to our mission of delivering innovative, safe, and efficient engineering solutions. Our commitment to excellence, powered by state-of-the-art FEA capabilities, ensures that we turn conceptual challenges into tangible successes for our clients.Are you ready to elevate your projects with unparalleled accuracy and insight?

Contact ENSER today to learn how our FEA services can transform your engineering challenges into triumphs. Let's turn your concepts into reality, together.