Delving into FEA Services: From Concept to Reality in Structural Analysis

March 19, 2024

Team Arnone Participates in the PanCAN PurpleStride Philadelphia 2024 Walk

April 4, 2024In manufacturing, where efficiency and precision dictate success, the strategic use of precision tooling, like jigs and fixtures plays a pivotal role. These essential tools not only streamline production processes but also ensure the consistent quality and accuracy of manufactured parts. For over seven decades, ENSER Corp has been at the forefront of delivering custom tooling and fixture solutions to a diverse array of industries, including power generation, automotive, aerospace, and others. Our experience has taught us the value of these tools in enhancing productivity. This blog post aims to share best practices for utilizing jigs and fixtures, drawing on our extensive background to help mechanical engineers optimize their production lines.

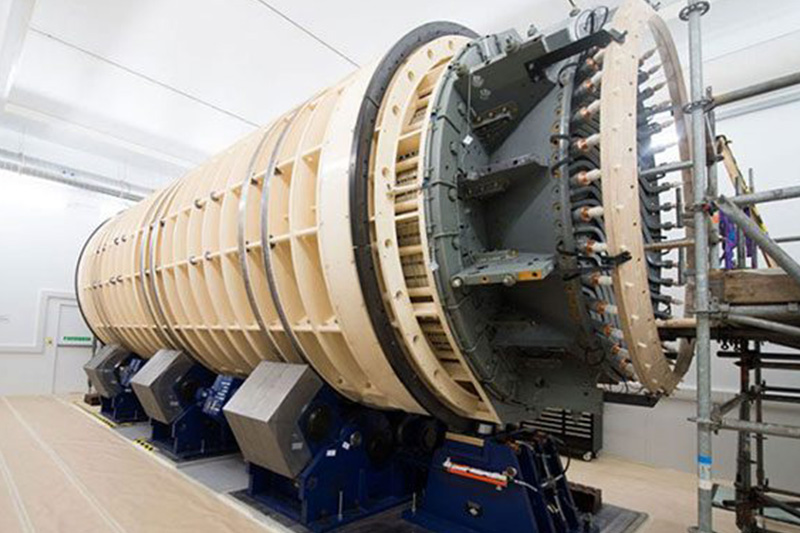

The Vital Role of Jigs and Fixtures in Manufacturing

Jigs and fixtures are tools specially designed to hold, support, and locate every part precisely, ensuring that every component is manufactured within the required tolerances. They are crucial for repetitive assembly and machining operations, allowing for faster production times without sacrificing quality.Six Essential Best Practices for Superior Jig and Fixture Tooling Design

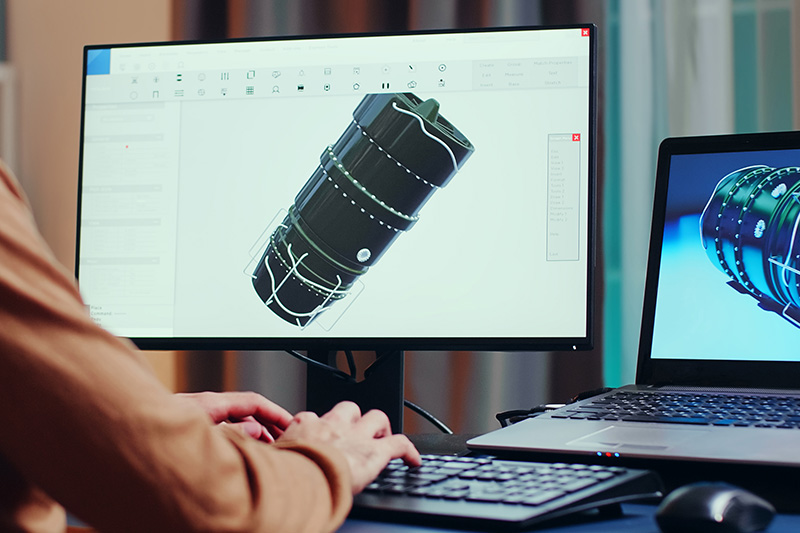

Leveraging our decades of cross-industrial expertise, ENSER Corp has established itself as a leader in custom tooling solutions, adapting and innovating through the decades to meet the evolving demands of manufacturing. Our journey since 1947 has endowed us with unparalleled insights into the intricacies of jig and fixture tooling design, enabling us to refine a set of best practices that stand as the cornerstone of precision, efficiency, and quality in production. These practices, distilled from our rich history of serving diverse industries, embody the essence of our commitment to excellence.- Evaluate Production Requirements: Tailoring jigs and fixtures to meet specific production needs is essential. Our years of experience working across industries like aerospace, automotive, and power generation have honed our ability to assess and meet unique manufacturing challenges.

- Design for Precision and Durability: Precision in the design of jigs and fixtures is critical. At Enser Corp, we focus on creating tools that guarantee accuracy and repeatability, using materials that withstand the rigors of production environments.

- Customization Is Key: Our approach emphasizes the customization of jigs and fixtures to fit the needs of each project. This custom service approach ensures that our clients in power generation, aerospace, automotive, and other sectors receive solutions perfectly aligned with their operational requirements.

- Prioritize Safety and Ergonomics: The well-being of the workforce is paramount. Our designs incorporate ergonomic considerations and safety features to minimize fatigue and risk, a practice developed through our extensive experience in diverse manufacturing settings.

- Incorporate Adjustability and Flexibility: Given the varying demands of the industries we serve, from automotive to aerospace, the adaptability of jigs and fixtures is crucial. We design our tools for versatility, accommodating changes in production processes and part designs.

- Regular Maintenance and Upkeep: The longevity of jigs and fixtures is significantly extended through proper maintenance. Drawing on our experience across various industries, we advise on best practices for the care and upkeep of these essential tools.

Why ENSER Stands Out in the Custom Tooling Solutions Industry

Our commitment to excellence, driven by decades of experience in providing custom tooling and fixture solutions, positions ENSER Corp as a leader in the field. Our history of serving diverse industries has equipped us with the insights to create solutions that meet the specific needs of our clients, ensuring their manufacturing processes are as efficient and precise as possible. Jigs and fixtures are indispensable in achieving streamlined production, and the expertise ENSER Corp brings to the table in designing these tools is unmatched.Empowering Innovation: Your Ideas, Your Ownership

We firmly believe in empowering our clients' innovations by ensuring that when we collaborate on a project, the intellectual property (IP) and final products belong entirely to you. This commitment sets us apart in the industry, offering a unique assurance that all designs, tooling solutions, and technological advancements developed in our partnership are yours to own, with no restrictions, retention clauses, or revenue sharing agreements. Ever. We understand the value of your ideas and the importance of maintaining control over your creations. By entrusting us with your projects, you gain not just a service provider, but a partner dedicated to fostering your success while ensuring your innovations remain exclusively yours. This approach not only respects your rights but also encourages a culture of open innovation and trust, paving the way for groundbreaking advancements.Optimize Your Production with Custom Tooling and Fixtures

Optimize your manufacturing processes with ENSER Corp's custom-designed tooling and fixtures. Contact us today to learn how our expertise can benefit your production line, ensuring precision, efficiency, and quality in every part you produce.