Spreader Bars: The Versatile Tools for Safe and Efficient Material Handling

February 26, 2024

Unlock Your Engineering Career Potential with ENSER & The Resume Team

March 12, 2024The safety and efficiency of lifting heavy loads are paramount, particularly in industrial settings. At ENSER, a leader in engineering services with a rich history since 1947, we understand the critical role that below the hook lifting devices, particularly lifting beams, play in achieving these goals. This article delves into the essentials of lifting beams, showcasing how they are indispensable tools for enhancing safety, optimizing load distribution, and ensuring compliance with industry standards.

The Imperative for Safety and Precision in Load Handling

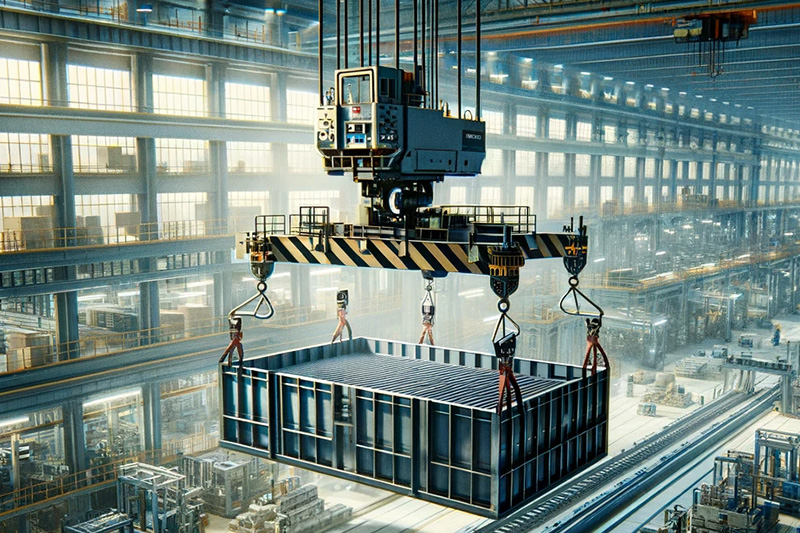

Industrial settings are characterized by the movement and assembly of heavy loads, where precision and safety are non-negotiable. Lifting beams, as a category of below the hook lifting devices, are engineered to meet these demands, offering a solution that not only safeguards the workforce but also protects the integrity of the materials being handled. Their design ensures even load distribution, mitigating the risks of accidents and facilitating compliance with stringent safety regulations, such as those set forth by OSHA and other international bodies.Engineering Excellence in Load Distribution

Lifting beams epitomize engineering ingenuity, designed to distribute loads evenly across multiple points. This uniform distribution is crucial for maintaining balance and stability during lifting operations, preventing tilts and sways that could lead to catastrophic failures. At ENSER, our approach to below the hook lifting devices encompasses a comprehensive analysis to tailor each beam to the specific needs of our clients, from the power generation sector, to automotive, aerospace, and other sectors.Material and Design Considerations

The selection of materials for lifting beams prioritizes strength, durability, and compliance with industry standards. Utilizing advanced materials such as high-strength steel alloys, we engineer lifting beams to withstand the rigors of industrial use. Through Finite Element Analysis (FEA), our engineers simulate real-world conditions to optimize the beam's design, ensuring it can handle specified loads with utmost reliability.Below-the-Hook (BTH) Requirements

Adhering to Below-the-Hook requirements is not just about meeting legal standards; it's about ensuring the safety and efficiency of lifting operations. Our designs undergo rigorous testing and certification processes, ensuring they meet or exceed industry standards like ASME BTH-1 and ASME B30.20 (Learn more about our primer on ASME B30.20) This meticulous attention to compliance underscores our commitment to delivering lifting solutions that clients can trust for their critical operations.Custom Fabrication for Unmatched Adaptability

No two industrial operations are exactly alike, which is why the custom fabrication of lifting beams, and other below the hook lifting devices, like spreader bars, becomes a game-changer. ENSER’s legacy in custom engineering solutions shines through in our ability to create lifting beams that cater to the unique requirements of each project. Whether adjusting for load size, shape, or weight, our bespoke designs enhance operational efficiency, demonstrating our versatility and commitment to client satisfaction.Case Studies: Transforming Industrial Operations

In one of our challenging and rewarding below the hook lifting device project, ENSER engineered a groundbreaking solution for a client, in the power generation industry, requiring an exceptional 300-ton lifting beam. This case study exemplifies the pinnacle of engineering ingenuity and tailored design, addressing the unique demands of lifting an extraordinarily heavy load with precision and safety. Our team implemented a meticulous design process which included employing advanced Finite Element Analysis (FEA) to ensure the beam's integrity under extreme conditions. The result was not just a lifting beam but a testament to our commitment to pushing the boundaries of what's possible with below the hook lifting devices. This project underscores our capability to deliver custom-engineered solutions that meet our clients' most demanding requirements, setting new industry standards for safety, efficiency, and reliability.Elevating Safety and Efficiency with ENSER

For over seven decades, ENSER has been at the forefront of engineering innovation, providing project management and engineering services that embody quality and dependability. Our expertise in below the hook lifting devices, particularly lifting beams, is a testament to our dedication to elevating safety and efficiency in industrial settings. By partnering with ENSER, clients gain access to a team of experts committed to delivering tailored solutions that meet the highest standards of safety and performance.A Trusted Partner in Industrial Lifting Solutions

In industrial operations, the need for reliable, efficient, and safe lifting solutions remains constant. Lifting beams, as critical components of below the hook lifting devices, play a vital role in meeting these needs. At ENSER, our commitment to engineering excellence, safety, and client satisfaction positions us as a trusted partner for industries seeking to maximize their lifting operations' safety and load distribution.Elevate Safety and Efficiency with ENSER’s Expertise

Whether you're looking to enhance the safety of your lifting operations, comply with industry standards, or optimize your load handling processes, ENSER is here to provide the expertise and solutions you need. Contact us today to learn more about our below the hook lifting devices and how we can tailor our engineering services to meet your project's specific requirements.