Engineering Confidence with Finite Element Analysis

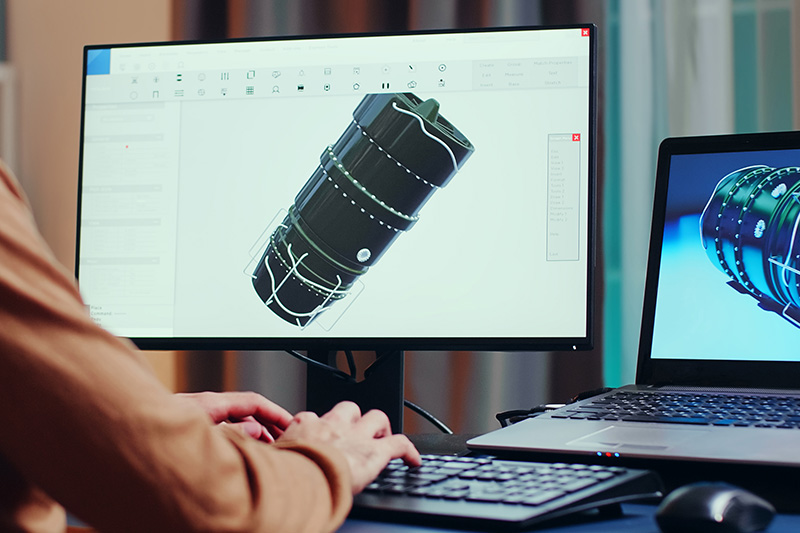

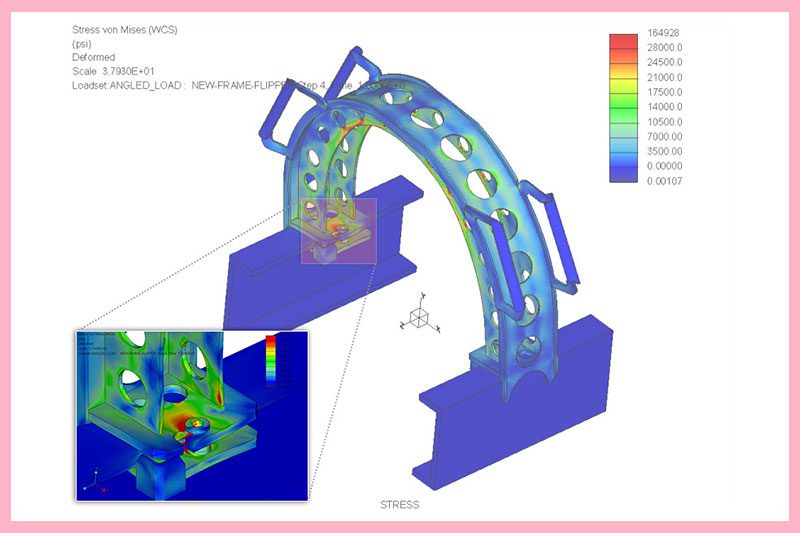

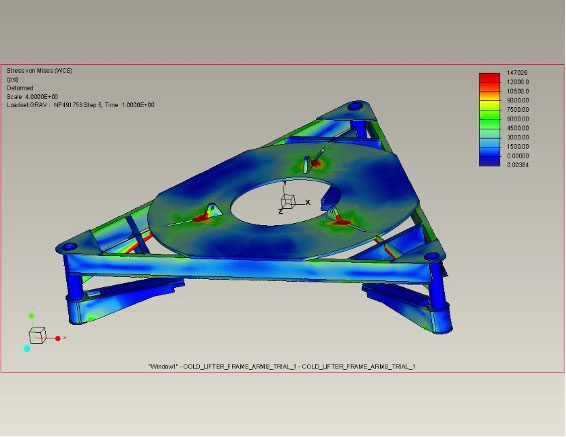

When precision, performance, and safety are non-negotiable, Finite Element Analysis (FEA) is the engineering tool of choice. At ENSER Corporation, we leverage FEA to provide insight-driven design validation, structural optimization, and risk mitigation across a wide range of industries—from aerospace and automotive to energy, industrial machinery, and defense. FEA isn't just a simulation method—it's a way to reduce physical prototyping costs, prevent design flaws, and shorten product development cycles. Our in-house team of engineers brings decades of experience and a deep understanding of physics, materials, and boundary conditions to every analysis we perform. Whether you're troubleshooting an existing product or validating a brand-new design, FEA offers the data-driven assurance that every component is engineered for success. Explore one of our recent successes in our FEA-Backed Automotive Torque Machine Case Study to see how simulation can prevent costly oversights and improve product lifespan.

What is Finite Element Analysis?

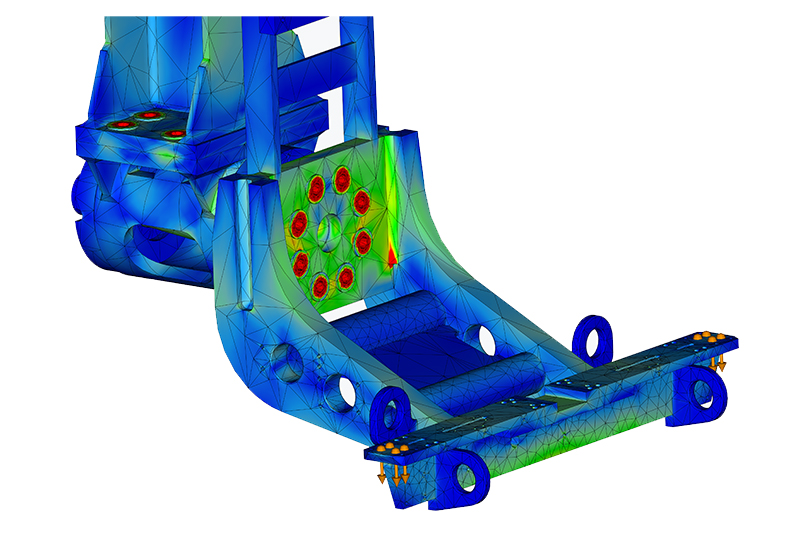

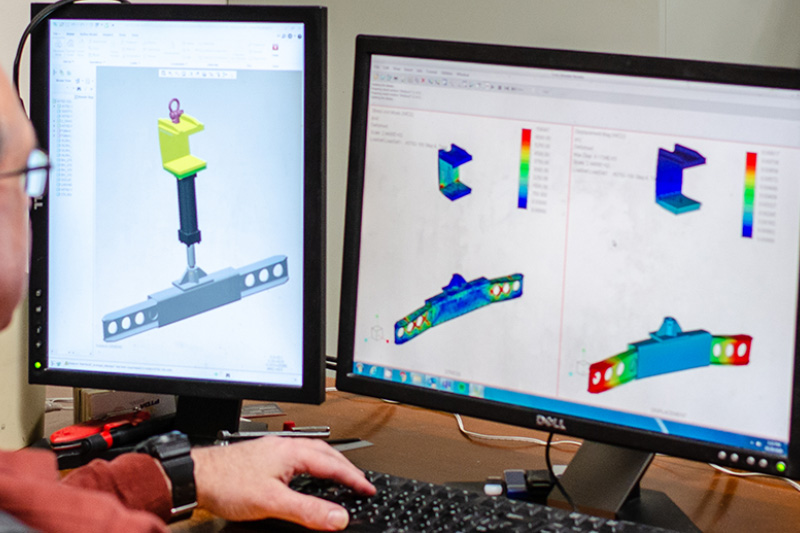

Finite Element Analysis (FEA) is a simulation technique used to predict how a product or component reacts to real-world forces such as heat, vibration, fluid flow, and other physical effects. It breaks down complex geometries into smaller “elements” to calculate stress, strain, and deformation—before a single part is manufactured.

To us FEA is more than just a simulation. It’s an integral part of how we engineer success for our clients. Whether it's stress testing a critical component or optimizing an existing design for cost savings, we use FEA to bring confidence and precision to every project.

When Should you use FEA?

Why Choose ENSER for FEA?

We don’t just run simulations—we solve problems. ENSER has been supporting engineering projects since 1947. Our team understands the manufacturing and real-world constraints that affect your designs, and we bring that expertise into every analysis.

- Integrated with Design & Manufacturing: Our FEA insights directly inform our in-house Tooling & Fixtures and Turnkey Manufacturing Services.

- Experienced Engineers, Not Just Analysts: We don’t hand off your file to a software operator—we apply real engineering judgment.

- Proven Track Record: Our case studies highlight successful projects where FEA played a critical role.

Our FEA Capabilities

Structural Analysis

Linear and nonlinear stress analysis

Static and dynamic loading conditions

Buckling and collapse predictions

Fatigue and fracture analysis

Post-yield and plastic deformation simulations

Submodeling for localized stress concentration

Thermal Analysis

Heat transfer (conduction, convection, radiation)

Steady-state and transient thermal simulations

Thermal expansion and stress

Cooling system evaluation

Thermally induced fatigue analysis

Modal & Vibration Analysis

Natural frequency identification

Harmonic response

Random vibration and shock response

Mode shape visualization

Vibration mitigation strategies

Contact & Assembly Analysis

Complex multi-part interactions

Weldment simulation

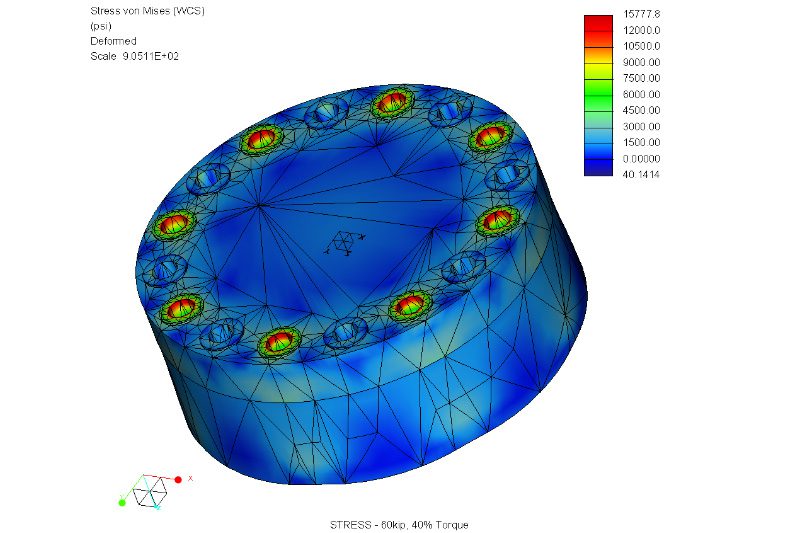

Bolted and riveted connections

Frictional contact and separation behavior

Preload simulation for fasteners

Specialized Simulations

Drop test simulation

Thermal-mechanical coupling

Large deformation and plasticity

Composite material analysis

Time-dependent material behavior (creep, relaxation)

Manufacturing process simulations (forming, stamping, curing)

Industries We Support

- Aerospace: Optimize weight and structural integrity for flight-critical components. Ensure durability in high-vibration and pressurized environments. Use modal analysis to avoid resonant frequency issues.

- Automotive: Validate crashworthiness, NVH (noise, vibration, and harshness), fatigue life of chassis components, and thermal stability of underhood assemblies. Support design of electric vehicle battery casings and cooling systems.

- Energy: Ensure structural integrity of turbines, piping systems, and support structures under thermal and mechanical loading. Analyze thermal stresses in weldments, simulate pressure cycling effects, and model fluid-structure interaction.

- Industrial Equipment: Optimize weight and structural integrity for flight-critical components. Ensure durability in high-vibration and pressurized environments. Use modal analysis to avoid resonant frequency issues.

- Defense: Validate crashworthiness, NVH (noise, vibration, and harshness), fatigue life of chassis components, and thermal stability of underhood assemblies. Support design of electric vehicle battery casings and cooling systems.

Real-World Impact

In our project involving the Power Rollers for a 300-Ton Generator, ENSER engineered a system of power rollers designed to rotate a massive stator core during the winding process. By applying FEA, we ensured the rollers could withstand the substantial loads and stresses involved, enhancing manual handling, safety, and quality. This analysis was crucial in validating the design before fabrication, ensuring reliable performance in the field.

Common FEA Pitfalls - And How ENSER Avoids Them

While FEA is a powerful tool, its effectiveness depends on the quality of the setup and interpretation. At ENSER, we frequently help clients who received flawed simulations from less experienced providers. Some common pitfalls include:

- Improper boundary conditions that don’t reflect real-world constraints

- Poor meshing practices leading to inaccurate stress concentrations or numerical noise

- Material misrepresentation such as assuming linear behavior where nonlinear properties are critical

- Ignoring contact behavior or oversimplifying joints and interfaces

Our analysts follow a robust quality-check process that includes:

- Mesh convergence studies

- Load path verification

- Physical review of design intent with manufacturing and testing teams

- Peer reviews before reporting results

- We treat FEA as an engineering discipline—not just a software skillset.

We treat FEA as an engineering discipline—not just a software skillset.

WE WORK WITH THE BEST

Getting Started with ENSER

Whether you're new to FEA or an experienced design team looking for expert support, our process is structured to fit your needs:

What to Expect

This process is flexible. Whether you need a single quick-turn analysis or an ongoing partner for simulation-integrated design, ENSER is ready to support your product development goals.

Frequently Asked Questions

FEA Articles

Need Confidence in Your Design? Let’s Simulate Success.

Whether you’re fine-tuning an existing part or building something brand new, ENSER’s Finite Element Analysis services give you the data to move forward with certainty. Let’s put your design to the test—before it hits the production floor.

Stay Ahead with the Latest in Engineering,Manufacturing & Staffing

Get expert insights, industry trends, and practical solutions delivered straight to your inbox. Subscribe to our newsletter and never miss an update from ENSER.