Below-the-Hook Lifting Devices

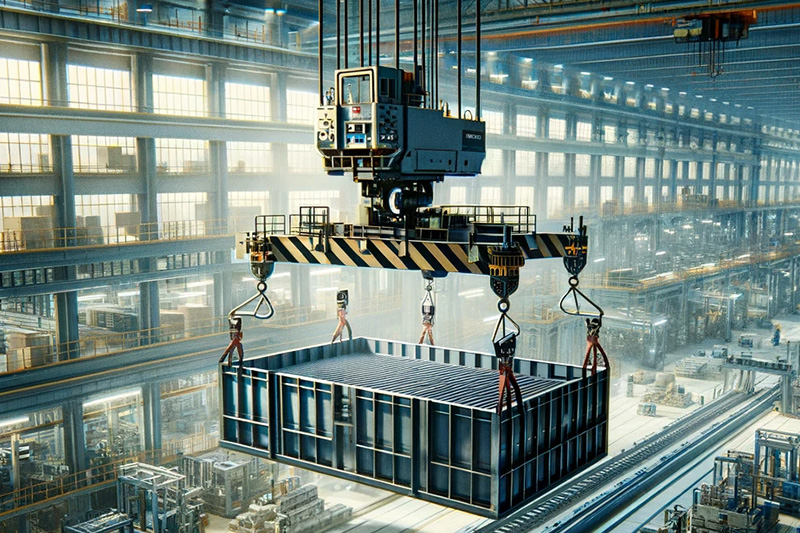

Custom-Engineered Lifting Devices that Put Safety First. At ENSER, we don’t believe in one-size-fits-all—especially when lives and loads are on the line. Our custom-engineered Below-the-Hook (BTH) lifting devices are purpose-built for your application, ensuring every lift is safe, ergonomic, and efficient.

What Is a Below-the-Hook Lifting Device?

A Below-the-Hook (BTH) lifting device is any tool or apparatus that attaches to a crane or hoist and secures a load during lifting. These devices are often engineered for specific parts, assemblies, or handling environments and must comply with strict safety standards such as ASME B30.20. From mechanical lifters and spreader beams to vacuum grips and multi-point fixtures, ENSER designs BTH devices tailored to your manufacturing, maintenance, or assembly process.

Enser's BTH Engineering Capabilities

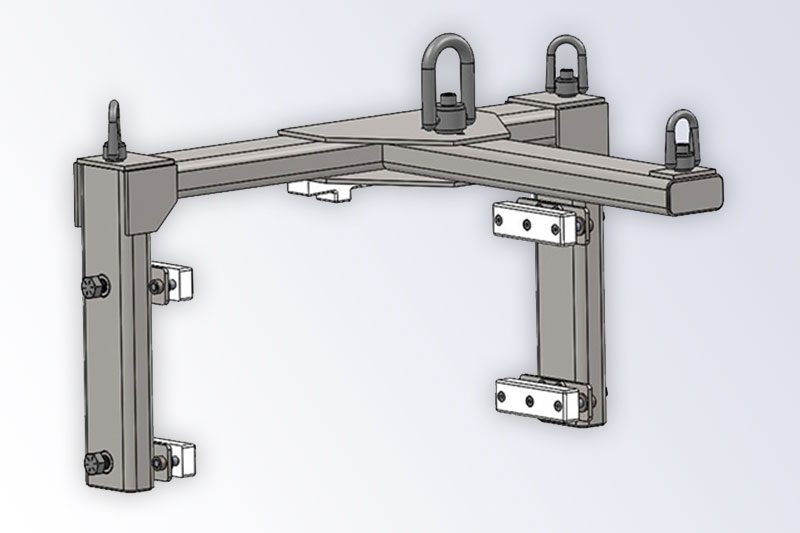

Custom Design and Simulation

We engineer lifting devices specific to your load geometry, weight, center of gravity, and handling requirements—never off-the-shelf, never guesswork.

ASME Compliance

Every ENSER BTH device is designed to meet or exceed ASME B30.20 and BTH-1 standards, including structural calculations and inspection plans.

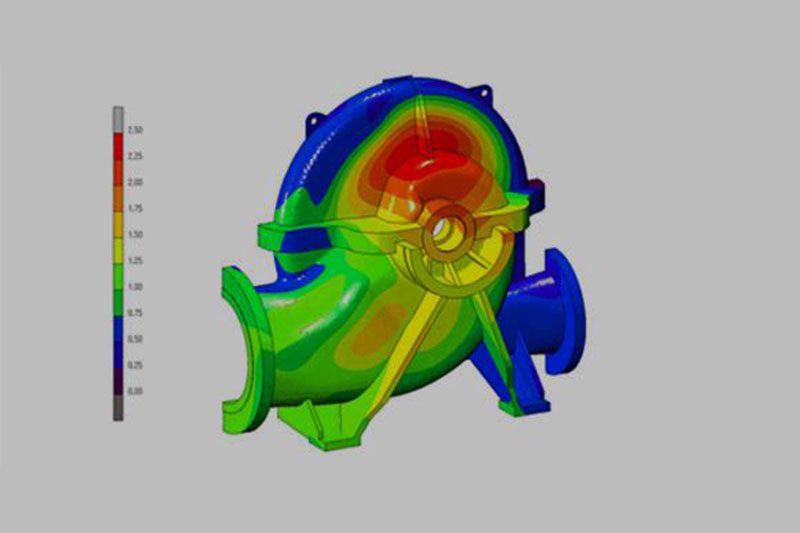

FEA-Driven Validation

Using Finite Element Analysis, we validate load paths, stresses, and deflections to ensure safe operation under real-world conditions.

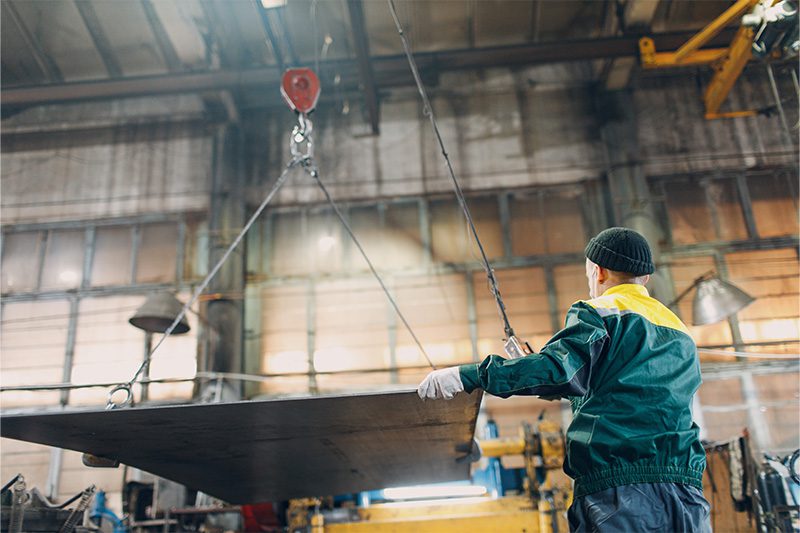

Ergonomics and Operator Safety

Ease of use is just as important as load capacity. We prioritize intuitive operation, minimized pinch points, and reduced strain during loading/unloading.

Fabrication Support

Already have a fabricator or need one? ENSER provides full manufacturing drawings and support—paired seamlessly with our Turnkey Manufacturing Services.

Industries We Support

- Aerospace: Optimize weight and structural integrity for flight-critical components. Ensure durability in high-vibration and pressurized environments. Use modal analysis to avoid resonant frequency issues.

- Automotive: Validate crashworthiness, NVH (noise, vibration, and harshness), fatigue life of chassis components, and thermal stability of underhood assemblies. Support design of electric vehicle battery casings and cooling systems.

- Energy: Ensure structural integrity of turbines, piping systems, and support structures under thermal and mechanical loading. Analyze thermal stresses in weldments, simulate pressure cycling effects, and model fluid-structure interaction.

- Industrial Equipment: Optimize weight and structural integrity for flight-critical components. Ensure durability in high-vibration and pressurized environments. Use modal analysis to avoid resonant frequency issues.

- Defense: Validate crashworthiness, NVH (noise, vibration, and harshness), fatigue life of chassis components, and thermal stability of underhood assemblies. Support design of electric vehicle battery casings and cooling systems.

Real-World Impact

In one of our featured case studies, a customer needed a lifting solution to safely position and secure heavy subassemblies during final assembly of large machinery. ENSER designed a custom BTH device that aligned with their cycle time, ergonomic needs, and uptime requirements. The result? Safer, faster, and more repeatable operations—delivered on spec and on time.

Why ENSER For BTH Devices?

Engineering Experience: Trusted since 1947, we’ve designed hundreds of lifting solutions across industries.

Cross-Disciplinary Team: Our mechanical designers work side-by-side with simulation experts and field engineers.

End-to-End Capability: From concept to fabrication, ENSER can handle the full lifecycle—or plug in where needed.

Traceability and Safety-First Culture: We deliver lift plans, inspection protocols, and training documentation with every project.

Related Services

- Finite Element Analysis (FEA)

- Engineering Staffing

- Tooling & Fixtures

- Turnkey Manufacturing Services

WE WORK WITH THE BEST

Getting Started with ENSER

Designing a custom BTH lifting device doesn’t need to be complicated. Here’s how we make it seamless, from first call to final delivery.

What to Expect

Frequently Asked Questions

BTH Articles

Ready to Design Your Next Lift?

Custom BTH Devices—Because Safety Is Never Optional

If you’re lifting heavy, awkward, or high-value components, don’t settle for generic. ENSER’s custom BTH lifting devices are built around your part, your people, and your process.

Stay Ahead with the Latest in Engineering,Manufacturing & Staffing

Get expert insights, industry trends, and practical solutions delivered straight to your inbox. Subscribe to our newsletter and never miss an update from ENSER.