Empowering Dreams: ENSER Corporation Honors the Arnone Foundation Scholarship at Temple University’s Fall Scholarship Celebration

December 5, 2023

Unveiling the Future, Engineering Trends in Labor and Manufacturing

January 30, 2024In the dynamic world of manufacturing, efficiency and precision are paramount. Mechanical engineers play a crucial role in achieving these goals, especially when it comes to tooling and fixtures. This blog post explores the best practices that mechanical engineers can adopt to streamline production processes and enhance overall manufacturing performance.

Comprehensive Understanding of Requirements

Before diving into the design phase, mechanical engineers must have a thorough understanding of the manufacturing requirements. This involves close collaboration with the production team, acquiring insights into material specifications, tolerances, and production volumes. A clear understanding of the project scope ensures that the tooling and fixtures designed are tailored to meet specific needs.Embracing Precision Tooling

Precision is the hallmark of successful manufacturing processes. Engineers should prioritize the use of precision tooling in their designs. This includes high-quality cutting tools, measurement instruments, and CNC machinery. Investing in precision tools not only ensures accuracy but also contributes to the longevity of the fixtures and jigs, reducing the need for frequent replacements.Custom Fixtures for Unique Challenges

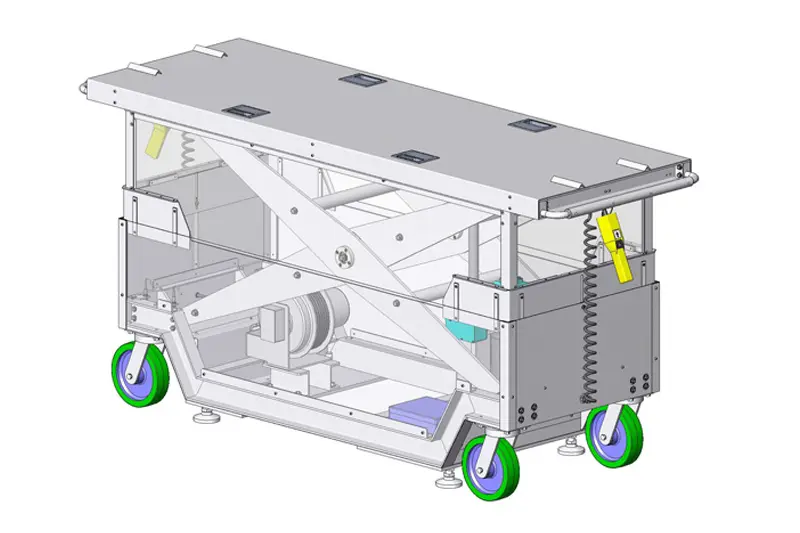

Every manufacturing project comes with its own set of challenges. Mechanical engineers should not shy away from creating custom fixtures to address unique requirements. Tailoring fixtures to specific tasks can lead to improved efficiency and higher-quality output. Customization allows for adaptability, especially in industries where product designs are diverse.Integrated Tool Design

Seamless integration between tools and fixtures is vital for a smooth production workflow. Engineers should design tools and fixtures in tandem, ensuring they complement each other perfectly. This integrated approach minimizes downtime, enhances precision, and optimizes the overall manufacturing process.Prototyping for Perfection

Prototyping is an invaluable step in the tooling and fixture design process. Creating a prototype allows engineers to test and refine their designs before full-scale production. This iterative approach ensures that the final tools and fixtures meet performance expectations, mitigating potential issues and reducing costly modifications during the production phase.Robust Fixture Design

The design of fixtures should prioritize durability and stability. Engineers must account for the forces and stresses exerted during the manufacturing process. A robust fixture design not only extends the lifespan of the tools but also contributes to the safety of the production environment.Assembly Tools for Efficiency

Efficient assembly is a key factor in overall production efficiency. Mechanical engineers should focus on designing assembly tools that are ergonomic, easy to use, and promote swift assembly processes. This not only enhances productivity but also minimizes the risk of errors during the assembly phase.Continuous Improvement

The field of manufacturing is ever evolving, with new technologies and methodologies emerging regularly. Mechanical engineers should actively seek opportunities for continuous improvement. Staying updated on industry trends, incorporating feedback from production teams, and embracing new technologies ensures that tooling and fixtures remain at the forefront of efficiency and innovation. In conclusion, mechanical engineers play a pivotal role in optimizing production processes through effective tooling and fixture design. By adhering to best practices such as understanding project requirements, prioritizing precision tooling, embracing customization, and continuously seeking improvement, engineers can contribute significantly to streamlining production and achieving excellence in manufacturing. Adopting these practices positions mechanical engineers as key players in the pursuit of efficiency, accuracy, and innovation within the realm of tooling and fixtures.Ready to elevate your manufacturing efficiency?

Take the first step towards maximizing your production efficiency. Lean on our vast expertise in mechanical engineering and dive into our comprehensive guide on "Streamlining Production with Jigs and Fixtures: Best Practices for Mechanical Engineers" to revolutionize your approach to tooling and fixtures.