Should engineering be outsourced?

November 1, 2022

ENSER is recognized as one of the Top 250 Private Companies by NJBiz.com in its Book of Leaders

December 8, 2022With so many global catastrophes happening in the past two years, reshoring is on the rise in 2022. This huge increase in companies bringing work to the United States will lead to an estimated 350,000 new jobs in 2022. What is reshoring and why will it benefit the US manufacturing industry? Keep reading this guide for everything you need to know about the benefits of returning manufacturing services to the United States.

What Is Reshoring?

In the United States, many companies think that offshoring their manufacturing will save their company money. Because of this, they think that offshoring is better than manufacturing domestically. However, reshoring provides many more benefits. What is reshoring? This is the move to localized manufacturing. If a business moved its operations overseas, reshoring moves the operations back to where they originally started.

Why now?

In the United States, many companies think that offshoring their manufacturing will save their company money. Because of this, they think that offshoring is better than manufacturing domestically. However, reshoring provides many more benefits. What is reshoring? This is the move to localized manufacturing. If a business moved its operations overseas, reshoring moves the operations back to where they originally started.

- Offshoring originally gained its popularity in the 1980’s, enabling companies to become more profitable due to cheaper labor and less regulation overseas.

- Prior to Covid, Reshoring had seen a steady rise over the previous decade, stemming from protectionist tariffs, rising overseas labor costs, rising fuel costs, advances in robotic automation, and the increasing sentiment of bringing back Manufacturing jobs to the US.

- Once the Covid-19 Pandemic was in full swing in early 2020, the major flaws of the Offshoring business model became quickly apparent.

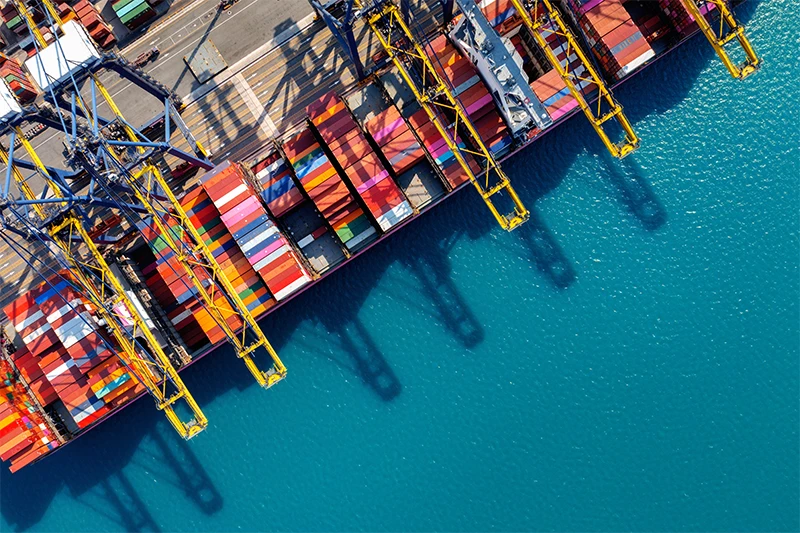

- Global Supply Chain disruptions caused substantial delays in shipping, and with it brought the business nightmare of Uncertainty.

- On top of the shipping issues, Covid led to many manufacturing facilities temporarily closing their doors to address Covid Outbreaks, which resulted in a production deficit.

- With many companies using lean, just-in-time manufacturing practices, there was not an adequate reserve of goods to weather the increasing supply deficit.

- This led businesses to investigate alternative options for production, such as reshoring.

Opportunities With Reshoring

There are many benefits that come with reshoring, which is why more companies than ever are switching to US manufacturing. This is also why ENSER has been part of American Made Matters since 2013.

Here are some of the top opportunities and benefits that come with reshoring!

1. Increased Profits

- Reshoring can provide business owners with increased profits. While many businesses offshore their operations to save money on their bottom lines, this is a short-sighted point of view.

- Higher fuel costs, increased tariffs, and increasing labor costs are making manufacturing overseas more expensive than ever.

- Reshoring will help you lower these costs and can increase your business profits.

2. Increased Safety & Quality Control

- One of the biggest benefits of reshoring is that it provides your business with greater safety and quality control for your products.

- This is because manufacturing in the United States has higher standards for quality. So, your business takes on much less risk when you manufacture domestically.

- It can also lower your risk of product malfunction, which can be dangerous for both your employees and consumers. Having design and manufacturing engineers at the same production facility increases communication & efficiency while also minimizing production disruptions.

- Enser has two facilities that cover the Eastern Seaboard, in NJ and NC, expanding our localized reach and providing flexibility.

3. Saves Time & Transportation Costs

- Your business doesn’t have to go through the lengthy shipping process required when you have your business operations offshore, thus saving you time.

- With localized operations you have greater efficiency and faster results

- This will result in much shorter lead times during the production process.

- Shortening your lead times will not only increase your customer satisfaction, but it can also keep your shipping costs lower and increase the amount of money that goes into your pocket.

- Reshoring can also help you lower your transportation costs. When you have your business operations offshore, your products need to be shipped long distances across the world.

- Transportation costs used to be lower, which is why many businesses would move their manufacturing operations abroad to save money on other business costs. However, transportation costs are continuing to climb.

- Choosing to bring your manufacturing operations back to the United States will reduce your transportation and logistics costs, while also increasing the predictability of operations.

4. Avoids Supply Chain Uncertainties (and is better for the environment)

- Next, reshoring can help you avoid supply chain disasters. The global supply chain has been impacted by many things. This includes rising prices for raw materials, insufficient labor, congestion at ports, and more.

- These issues with the global supply chain force companies to switch COTS vendors due to supply disruptions.

- With reshoring, you can avoid many of these issues and more! Instead of dealing with these issues around the world, your products will be made domestically.

- And the bonus to avoiding reliance on the international supply chain is that it’s better for the environment.

- By cutting out unnecessary transportation of your products, you will greatly reduce the carbon footprint of your business.

- Most products are transported from overseas, which is not the most energy-efficient method of transportation.

- Complex supply chains are responsible for up to 90 percent of the Manufacturing Industry’s environmental impact

5. Local and National Economy

- Another great benefit of reshoring is that it allows you to reinvest in the United States. Bringing Manufacturing back to the US helps with:

- Adding local jobs, which will help improve local communities.

- Bring back the pride in American craftsmanship.

- Strengthening the national economy.

- Several Enser Clients have reshored their manufacturing operations, with Volvo notably adding more than 5,000 jobs and investing over a billion dollars of capital in US facilities over the last 2 years.

The Future of Reshoring

The future of reshoring is bright, especially with the rise of automation. In fact, automation and advances in robotics are making onshoring more widely available for business owners. Companies that are taking advantage of reshoring production of their products to the US, including more control over supply chains, lower transportation costs and more efficient logistics, increased quality, and overall customer satisfaction. In addition, reshoring is adding jobs to local economies and helping to increase the national economy.

According to the Kearny 2021 Reshoring Index, 92% of executives expressed positive sentiments towards reshoring, and 79% of executives with operations in China have either moved part of their operations to the US or are planning to move in the next 3 years. Furthermore, manufacturing imports from China continue to decrease from a 66% high in 2018 to 55% in 2021.

The future of onshoring is often referred to as a golden era of onshoring.

Learn More About the Benefits of Reshoring US Manufacturing Today

The COVID-19 pandemic that affected supply chains worldwide, and the current multinational tensions and conflicts have brought to focus the reliance on offshoring and how susceptible that model became to global events. Add to the mix the current geo-political landscape, including the war in Ukraine, and the offshoring benefits are swiftly eclipsed by the rising costs in transportation and logistics.

Although reshoring has been happening for several years, we have been directly involved with reshoring for nearly a decade, most companies are now realizing the importance of bringing back their productions to the US. Some sectors are better poised to take advantage of reshoring and manufacturing (including automotive, aerospace, and steel). If you have been concerned about current global events affecting your business and how your business can sustain the impact, now is the time to consider exploring reshoring opportunities.

Engineering, Manufacturing and Staffing Services

Talk to us, we have supported reshoring efforts since 2013, and can help you reshore your manufacturing initiatives