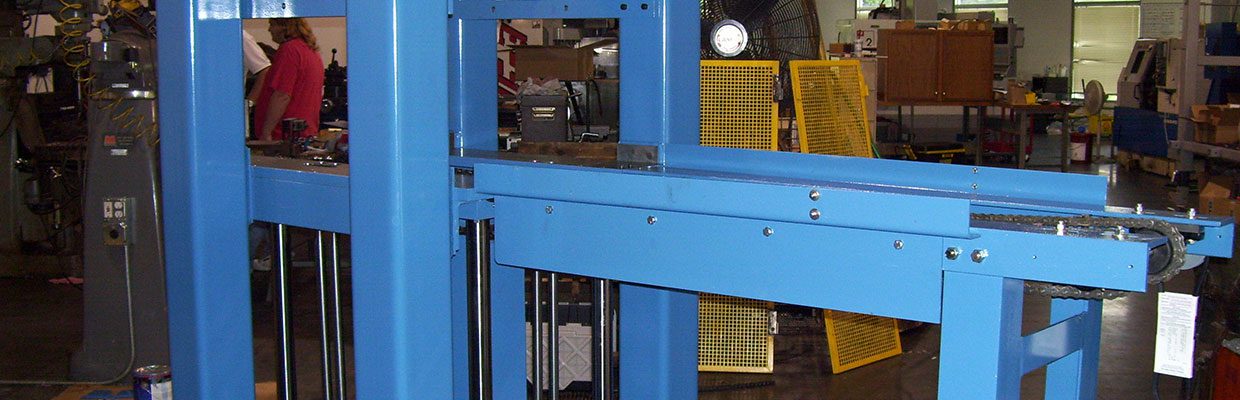

Automated Hole Punch Machine

Background

This unit was developed to automate a part loading and punching process currently performed manually.

Product

Automated Hole Punch Machine

Scope

ENSER worked with the company to design, build and install this automated hole punch machine. The system punched 3 holes at once and had a 30 second cycle time which was a 75% time savings. The parts could be easily stacked on a lead in conveyor and where automatically guided into the system where the sensors identified the size of the part and then located it properly for punching. The installation of this system increased throughput and operator safety.

Results

- Cycle time improved by 75%

- Non-conformance reduced 90%

- Labor reduced 27%

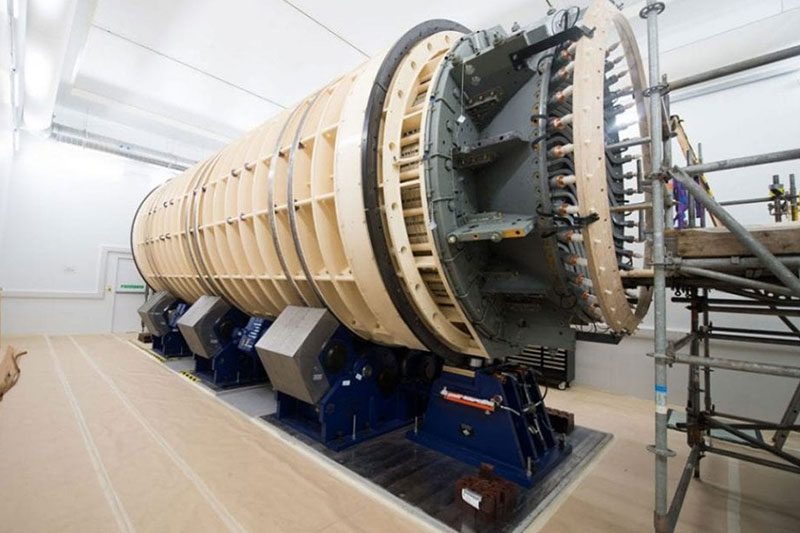

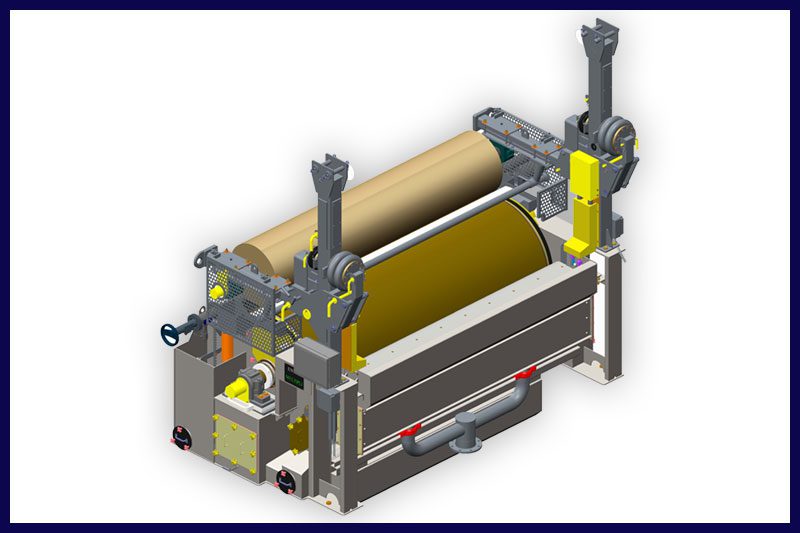

Engineering Services

Whether you need engineering services for the world's largest power rollers or something smaller, ENSER Corp, has the engineering skills and know-how to complete your project.