The Impact of AI on Recruiting: Transforming Talent Acquisition and the Job Market

April 9, 2025

Uncovering the Hidden ROI of Turnkey Manufacturing

June 4, 2025Introduction

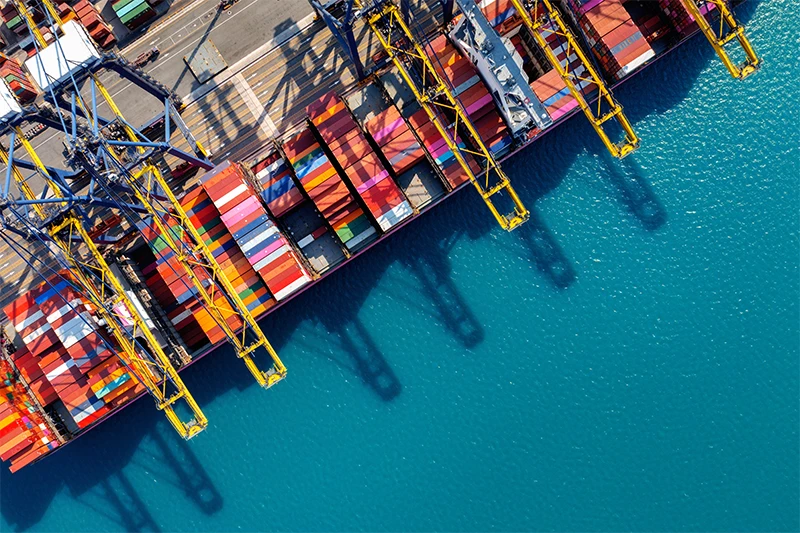

In recent years, the reshoring of manufacturing to the United States has gained significant momentum. This shift is largely driven by the uncertainty and volatility caused by recent tariffs, which have created numerous challenges for companies operating in global supply chains. This article explores the key pain points that companies face due to these tariffs and highlights the strategies they are employing to navigate this complex landscape, including how ENSER's engineering services can support these efforts.

The Reshoring Movement

Historically, many US companies offshored their manufacturing operations to countries with lower labor costs, such as China and Mexico. However, recent trends indicate a reversal of this practice, with a growing number of companies bringing their manufacturing back to the US. In 2023 alone, over 287,000 jobs were reshored, reflecting a significant increase in domestic manufacturing [1]. Key industries leading this movement include semiconductors, electric vehicles, and clean energy [1].

Impact of Tariffs on Manufacturing

The imposition of tariffs on various goods has had profound implications for manufacturing costs and supply chains. For instance, the 25% tariff on steel imports has significantly increased production costs for industries reliant on steel [2]. Additionally, federal policies such as the CHIPS Act and the Inflation Reduction Act have played a crucial role in encouraging reshoring by providing incentives for domestic manufacturing [1].

Pain Points for Companies Navigating Tariffs

Companies face several challenges as they navigate the complexities of tariffs:

- Increased Costs and Reduced Profit Margins: Tariffs have led to higher costs for raw materials and components, squeezing profit margins [3].

- Competitive Disadvantages: Companies subject to tariffs find themselves at a disadvantage compared to non-tariffed suppliers [3].

- Supply Chain Disruptions: Tariffs have disrupted supply chains, leading to extended timelines and increased uncertainty [4].

- Strained Supplier Relationships: The need to renegotiate contracts and find alternative suppliers has strained relationships with existing partners [4].

Strategies for Overcoming Tariff Challenges

To mitigate the impact of tariffs, companies are adopting several strategies:

- Leveraging Technology for Supply Chain Resilience: Advanced technologies such as AI and blockchain are being used to enhance supply chain visibility and resilience [5].

- Exploring Alternative Suppliers and Domestic Sourcing: Companies are increasingly looking for domestic suppliers to reduce dependency on foreign sources [5].

- Implementing Strategic Responses: Firms are investing in domestic manufacturing capabilities to maintain competitiveness. For example, Eli Lilly & Co. has announced a $27 billion investment in US manufacturing [1].

How ENSER Can Help

ENSER Corporation, with over 78 years of experience in engineering services, is uniquely positioned to assist companies in their reshoring efforts. ENSER offers a comprehensive range of services, including custom engineering solutions, manufacturing services, and engineering staffing solutions [6]. Here’s how ENSER can support reshoring initiatives:

- Custom Engineering Solutions: ENSER provides innovative and cost-effective engineering solutions tailored to meet the specific needs of each client. This includes design, testing, and analysis across various industries[6].

- Manufacturing Services: ENSER’s seasoned team ensures that manufacturing solutions are delivered on time and within budget, helping companies transition smoothly to domestic production[6].

- Engineering Staffing Solutions: ENSER offers specialized staffing services, providing skilled professionals to support reshoring projects and ensure that companies have the necessary expertise to succeed [6].

Conclusion

The reshoring of manufacturing to the US is a complex but necessary response to the challenges posed by recent tariffs. By understanding the pain points and adopting strategic measures, companies can navigate this uncertain landscape and contribute to the growth of domestic manufacturing. ENSER Corporation stands ready to support these efforts with its comprehensive engineering services. The future of reshoring looks promising, with continued support from federal policies and technological advancements.

Frequently Asked Questions About Engineering Staffing

Are You Ready to Optimize Your Domestic Manufacturing?

Navigating the complexities of tariffs and reshoring can be daunting, but you don't have to do it alone. ENSER Corporation is here to help you optimize your domestic manufacturing operations with our expert engineering services. Whether you need custom engineering solutions, reliable manufacturing services, or specialized staffing, ENSER has the expertise to drive your success. Visit enser.com to learn more about our services and how we can support your reshoring initiatives. Contact us today to discuss your specific needs and discover how our innovative solutions can transform your manufacturing operations. Let's work together to build a resilient and competitive future for your company.

References

- [1] The Reshoring Movement in American Manufacturing

- [2] 4 Ways Manufacturers Can Respond Strategically to the Impact of Tariffs

- [3] The Impact of Tariffs Across the US Supply Chain

- [4] How Tariffs Impact Supply Chains—and What Business Leaders Can Do About ...

- [5] 8 Strategies to Mitigate New Trade Tariffs | TrueCommerce

- [6] ENSER Corporation | Engineering, Manufacturing and Staffing Solutions