6th Annual Team Arnone PurpleStride Philadelphia 2017

August 30, 2017

52% of manufacturing companies outsource a portion of their workload

November 7, 2017HISTORY OF THE COUNTER FLOW WET VAT

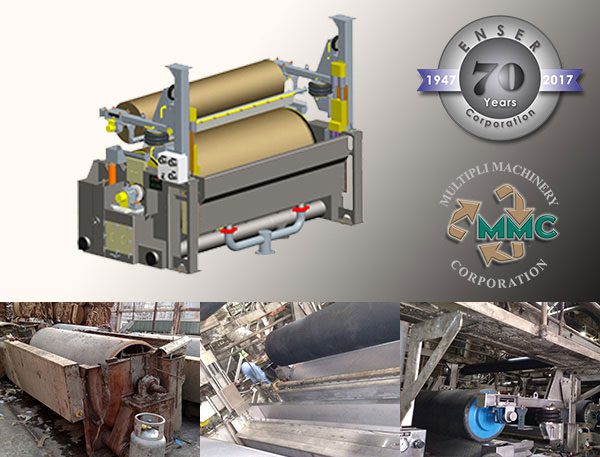

Paper mills are gaining a competitive advantage by replacing older style and aging counter flow wet vat machines with units designed by ENSER in partnership with MULTIPLI Machinery Corp. These new machines and improved stock delivery system provide an immediate and sustainable ROI through increased productivity, a better quality product and without the learning curve and costs of other forming equipment.

BACKGROUND

The project scope was the replacement of existing 36″ fiberglass vats with new stainless steel 42″ MULTIPLI Counter Flow Wet vat units. Each vat included a pneumatic air bellows couch lifting/loading system for use with the existing couch rolls. The machine was also equipped with a MULTIPLI designed automated CD profile control system. Additionally, new framing components were supplied to integrate the new vats into the existing wet end framing structure.

SCOPE

For this project, Enser partnered with MULTIPLI, the company that pioneered innovations in vat technology and is a leader in supplying many of the vats still in use today. Enser and MULTIPLI partnered to design, manufacture, assemble and deliver 6 MULTIPLI Counter Flow Wet Vat units designed for a cylinder of 42″ dia x 108″ face width to replace the much older existing 36″ fiberglass vats.

RESULTS

The results were increased mill productivity and higher quality product, which has led to more market share.

The process to replace the units was flawless, our client was up and running in one week.

Scott Bennett, President, MULTIPLI Machinery Corp.

Engineering Services

Whether you need engineering services for the world’s largest power rollers or something smaller, ENSER Corp, has the engineering skills and know-how to complete your project.