SPECIALIZED CUSTOM ENGINEERING SOLUTIONS

WHAT WE DO

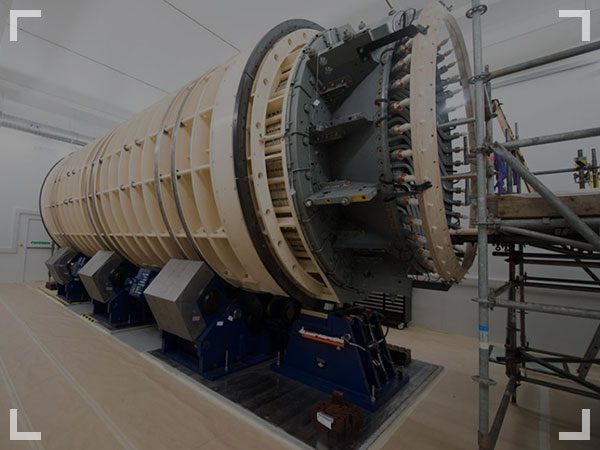

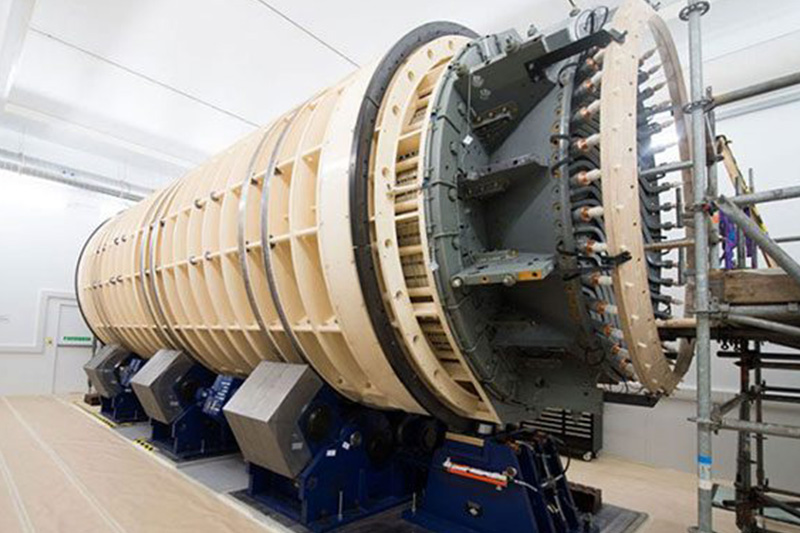

OUR CUSTOM ENGINEERING WORK SPEAKS FOR ITSELF

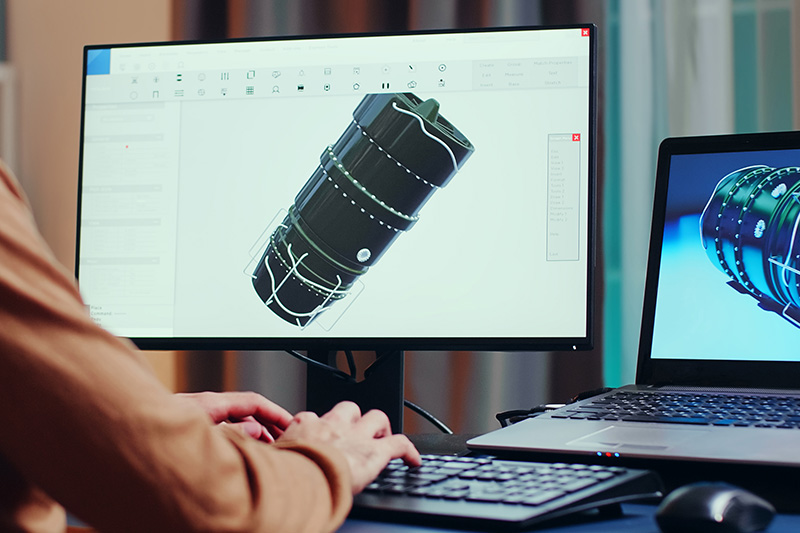

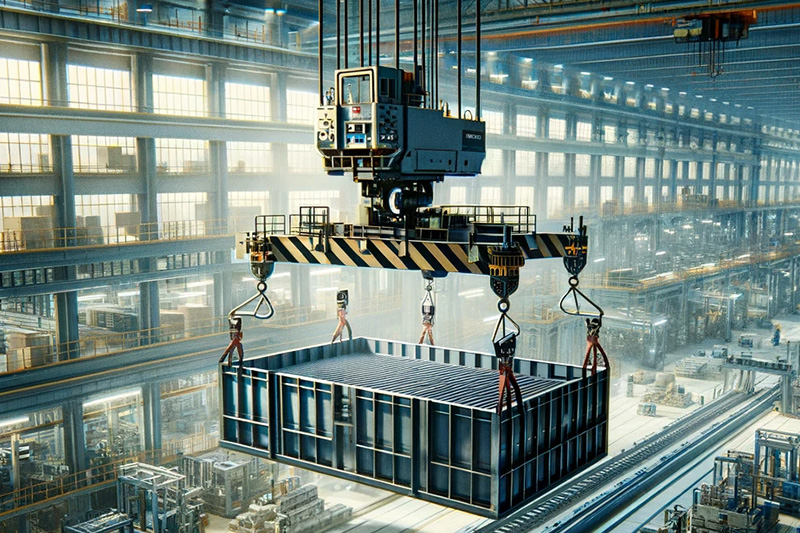

Since 1947, ENSER has offered innovative and cost-effective solutions in custom engineering services, ranging from design, testing and analysis in a myriad of industries. Other engineering companies do just one thing. Our competitive edge is derived from our ability to deliver diverse technology, performance, quality, cost and reliability, all from a single source, a complete turnkey solution.

MECHANICAL ENGINEERING ARTICLES

It is a big world out there for mechanical engineering companies. ENSER has been around for 76 years and knows a little something here and there about that big world. See below for mechanical engineering articles posted monthly.